Product classification

Incoloy825

Incoloy 825 is a fully austenitic nickel-iron-chromium alloy stabilized with titanium stabilized and copper and molybdenum added. Incoloy 825 It is a general-purpose engineering alloy that is resistant to acid and alkali metal corrosion in both oxidizing and reducing environments.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

Incoloy825

Incoloy 825 is a fully austenitic nickel-iron-chromium alloy stabilized with titanium stabilized and copper and molybdenum added. Incoloy 825

It is a general-purpose engineering alloy that is resistant to acid and alkali metal corrosion in both oxidizing and reducing environments.

Foreign name: Incoloy825 Applications: Air heat exchanger in petroleum refining Alloy properties Good resistance to stress corrosion

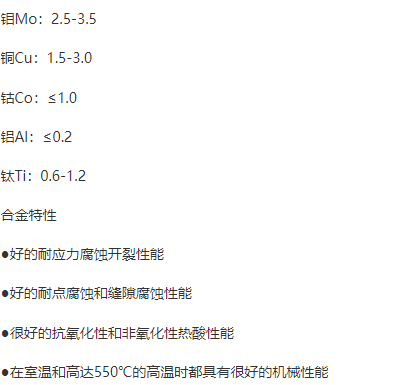

Cracking properties Chemical composition Nickel Ni: 38-46

Overview of alloys

The high nickel content gives the alloy effective resistance to stress corrosion cracking. Good corrosion resistance in a variety of media, such as:

Sulfuric acid, phosphoric acid, nitric acid and organic acids, alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solutions. Incoloy 825

The high overall performance is manifested in nuclear combustion dissolvers with various corrosive media, such as sulfuric acid, nitric acid and sodium hydroxide

Processed in the same device.

Similar grades

NS142 (China), NC21FeDu (France), W.N r.2.4858 NiCr21Mo (Germany) NA16 (UK)

Incoloy825, UNS NO8825 (USA) NiFe30Cr21Mo3 (ISO)

chemical composition

Nickel Ni: 38-46

Chromium Cr: 19.5-23.5

Iron Fe: Margin

Carbon C: ≤0.025

Manganese Mn: ≤1.0

Silicon Si: ≤0.5

Molybdenum Mo: 2.5-3.5

Previous Page

Next Page

Previous Page

Incoloy 800H

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!