Product classification

HastelloyX

Hastelloy X (N06002) is a nickel-based superalloy with high iron content mainly strengthened by chromium and molybdenum solid solution, with good nutrient and corrosion resistance, medium durability and creep strength below 900°C, good cold and hot working formability and welding performance. The combustion chamber parts and other high-temperature parts used in the manufacture of aero engines can be used for a long time below 900 °C, and the short-term working temperature can reach 1080 °C. The main varieties supplied are plates, strips, tubes, bars, forgings, rings and precision castings.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

HastelloyX

Material Grade: Hastelloy X Hastelloy

US Grade: UNS NO6002

German Grade: NiCr22FeMoBritish

Grade: Nimonic PE13

1. Overview of Hastelloy X (N06002) Hastelloy:

1. Hastelloy X (N06002) Hastelloy alloy is a nickel-based superalloy with high iron content mainly strengthened by chromium and molybdenum solid solution, with good nutrient resistance and corrosion resistance, medium durability and creep strength below 900 °C, good cold and hot working formability and welding performance. The combustion chamber parts and other high-temperature parts used in the manufacture of aero engines can be used for a long time below 900 °C, and the short-term working temperature can reach 1080 °C. The main varieties supplied are plates, strips, tubes, bars, forgings, rings and precision castings.

2. Chemical composition of Hastelloy X (N06002) Hastelloy: see Table 1-1.

Table 1-1

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | Cu≤ |

| 0.05-0.15 | 1.00 | 1.00 | 0.025 | 0.015 | 20.5-23.0 | Allowance | 8.0-10.0 | 0.50 |

| other | N≤ | Al≤ | Ti≤ | Fe≤ | Co≤ | V≤ | W≤ | B≤ |

| - | 0.50 | 0.15 | 17.0-20.0 | 0.5-2.5 | - | 0.2-1.0- | 0.010 |

Note: B is added according to the amount of calculation, not analyzed.

3. Hastelloy X (N06002) Hastelloy Heat Treatment System: Plates and Tubes: 1130~1170°C, Fast Air Cooling or Water Cooling; Bar and ring test specimens: 1175°C±15°C, air-cooled or faster cooled; Strip: 1065~1105°C, fast cooling.

4. Hastelloy X (N06002) Hastelloy Variety Specifications and Supply Status: Supply δ0.5~4.0mm plates, δ0.05~0.8mm strips, outer diameter 4~20mm, Pipes with a wall thickness of 1.0~2.0mm, welding wires with a diameter of 0.2~10.0mm, bars with a diameter of ≤300mm, rings with various diameters and wall thicknesses, and precision castings of different shapes and sizes. Plates, strips and pipes are supplied after solution treatment and pickling, and strips can also be supplied in a cold-rolled state; The welding wire is delivered in a tray, in a hard, semi-hard, solid melt plus pickling, and bright solution treatment state, or it can be delivered in a straight strip; Bars and rings are delivered without heat treatment. Precision castings are supplied in cast condition.

5. Hastelloy X (N06002) Hastelloy smelting and casting process: electric arc furnace plus electroslag or non-vacuum induction furnace plus electroslag remelting process. The production of castings is remelted by induction furnace and then poured in the heated mold shell, and the pouring speed is better.

6. Hastelloy X (N06002) Hastelloy Alloy Application Overview and Special Requirements: The alloy has been widely used in foreign aero engines and civil industries, and is mainly used in the manufacture of combustion chamber components and other hot end components and honeycomb structures in China. The alloy has a certain aging hardening phenomenon after long-term use at high temperatures.

2. Physical and chemical properties of Hastelloy X (N06002) Hastelloy:

1. Melting temperature range of Hastelloy X (N06002) alloy: 1295~1381 °C

2. Thermal conductivity of Hastelloy X (N06002) alloy: see Table 2-1

3. Specific heat capacity of Hastelloy X (N06002) alloy: Table 2-2

4. Hastelloy X (N06002) alloy line expansion coefficient: see Table 2-3

5. Thermal diffusivity of Hastelloy X (N06002) alloy castings: see Table 2-4

and Table 2-1

| θ/℃ | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| λ/(W/(m·℃)) | 13.38 | 17.97 | 20.27 | 22.40 | 24.62 | 26.79 | 29.05 | 31.14 | 33.44 |

Table 2-2

| θ/℃ | 17 | 100 | 200 | 280 | 408 | 500 | 700 | 800 | 900 |

| c/(J(kg·℃)) | 372.6 | 372.6 | 389.4 | 456.4 | 427.1 | 452.2 | 515.0 | 535.9 | 561.0 |

Table 2-3

| θ/℃ | 20~100 | 20~200 | 20~300 | 20~400 | 20~500 | 20~600 | 20~800 | 20~900 |

| α/10-6℃-1 | 12.1 | 12.5 | 13.4 | 14.0 | 14.3 | 14.8 | 15.8 | 16.1 |

6. Hastelloy X (N06002) density: ρ=8.28g/cm3

7. Hastelloy X (N06002) electrical properties: see Table 2-5

and Table 2-4 for resistivity

| θ/℃ | 24 | 100 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| Q/(10-6m2/S)) | 2.78 | 3.06 | 3.68 | 3.64 | 4.36 | 4.32 | 4.38 | 4.91 | 5.23 |

8. Hastelloy X (N06002) magnetic properties: the alloy is non-magnetic.

9. Chemical properties of Hastelloy X (N06002): see Table 3-1

10. Oxidation resistance of Hastelloy X (N06002): The oxidation rate of the alloy after 100 hours of testing in air medium is shown in Table 2-6

Table 2-5

| θ/℃ | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| p/(10-6Ω.M)) | 1.18 | 1.20 | 1.21 | 1.22 | 1.24 | 1.25 | 1.26 | 1.27 | 1.29 |

Table 2-6

| θ/℃ | 700 | 800 | 900 | 1000 | 1100 |

| Rate of oxidation/(g/(m.)2·h)) | 0.0023 | 0.060 | 0.117 | 0.200 | 0.611 |

3. Mechanical properties of Hastelloy X (N06002): The mechanical properties of different varieties specified in the HastelloyX technical standard are shown in Table 3-1

and Table 3-1

| variety | Tensile properties at room temperature | Long-lasting performance at 815°C | Other features | ||||

| σP0.2/MPa | σb/MPa | δ5/% | σ/MPa | t/h | δ5/% | ||

| Not less than | |||||||

| Cold-rolled sheets, cold-rolled strips, cold-drawn pipes, bars, rings Precision castings② |

310 310 310 275 275 200 |

725 760② 690 690 690 380 |

35 30① 25 30 30 10 |

110 - - 105 105 - |

24 - - 24 24 - |

8.0 - - 10.0 10.0 - |

Bending 180° Bending 180° Hydraulic, Flaring HBS≤ 241 HBS≤ 241 HBS≤96 |

(1) The tensile strength of δ<0.25mm strip at room temperature σ b≥725MPa, δ5≥25%.

(2) The casting state of precision castings is 815°C at σb≥240MPa, δ5≥12%. HRC≤24 after 800°C, 50h, and air cooling.

4. Microstructure of Hastelloy X (N06002) alloy:

1. Hastelloy X (N06002) alloy metal phase transition temperature

2, Hastelloy X (N06002) alloy time-temperature-microstructure

3, Hastelloy X (N06002) alloy microstructure

(1) The structure of the alloy in the solid solution state is austenitic matrix, and there are a small amount of TiN and M6Type C carbide. After long-term aging at 700~900°C, the main precipitated phases are M12C and M3B2, and there are also trace μ phases and L phases. After 700 °C and 200 h aging, a small amount of σ phase appears, but after 800 °C aging, σ phase does not exist, and trace amounts of M23C6 are precipitated, and sometimes trace L phases appear. Therefore, the alloy shows a certain degree of age hardening after long-term aging, which reduces the plasticity and high-temperature strength.

(2) The technical standard of cold-rolled sheet stipulates that the grain size of cold-rolled sheet in the supply state should be within the range of 4~8 grades.

5. Process performance and requirements of Hastelloy X (N06002) alloy:

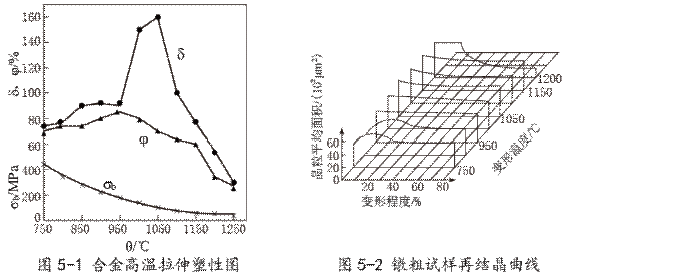

1. HastelloyX alloy forming performance: the alloy has good cold and hot processing forming properties. The forging heating temperature is 1170 °C± 10 °C, and the final forging temperature is not less than 950 °C; The heating temperature of slab hot rolling is 1150 °C± 10 °C, and the final rolling temperature is not less than 850 °C; The heating temperature of hot rolling of ring parts is 1170 °C ± 10 °C. The high-temperature tensile plasticity of the alloy is shown in Figure 5-1. The recrystallization curve of the high-temperature upsetting sample after solution treatment at 1180°C for 45min is shown in Figure 5-2.

2. HastelloyX welding performance: The alloy has good welding process performance, and can be welded by argon arc welding, seam welding and spot welding. For TIG welding, HHastelloyX or HGH3113 wire is recommended.

(1) See Table 5-1

and Table 5-1 for the specifications of HastelloyX manual argon arc welding butt

| The material to be welded | Thickness/mm | Pre-weld condition | welding wire | Joint form |

Welding current/A | Argon Flow/(L/min) | Tungsten electrode diameter/mm | Power supply and polarity |

|

| trademark | Diameter/mm | ||||||||

| HastelloyX+HastelloyX | 1.0+1.0 | Supply state or solution state | HHastelloyX HGH3113 |

1.2~1.6 | docking | 40~60 | 10~13 | 1.6~2.0 | DC positive polarity |

| 1.5+1.5 | HHastelloyX HGH3113 |

1.2~1.6 | 50~70 | 12~15 | 1.8~2.2 | ||||

(2) The specifications of HastelloyX automatic tungsten pulse argon arc welding are shown in Table 5-2

and Table 5-2

| Thickness/mm | Pre-weld condition | welding wire | Arc voltage/V | Pulse current/A | Dimension arc current/A | Pulse amplitude ratio | Pulse aspect ratio | Pulse frequency | Welding speed/(m/min) | Wire feeding speed/(m/min) | |

| trademark | Diameter/mm | ||||||||||

| 1.0 1.2 1.5 |

Solid solution | - HGH-1 HGH-1 |

- 1.0 1.0 |

8.5 8.5 9.0 |

60 65 100 |

20 22 28 |

3 3 3.5 |

2 2 2 |

3 3 3 |

0.25 0.2 0.23 |

- 0.20 0.25 |

(3) See Table 5-3

and Table 5-3 for HastelloyX seam weld specifications

| The material to be welded | Thickness/mm | Pre-weld condition | Disc width/mm | Welding time/s | Rest time/s | Welding speed/(m/min) | Electrode pressure/kN | |

| above | under | |||||||

| HastelloyX+HastelloyX | 1.0+1.0 | Solution or supply status | 5.5 | 7.0 | 0.14-0.18 | 0.14-0.22 | 0.34-0.40 | 0.25 |

| 1.5+1.5 | 5.5 | 7.0 | 0.16-0.20 | 0.14-0.22 | 0.22-0.34 | 0.25 | ||

(4) See Table 5-4

and Table 5-4 for HastelloyX spot welding specifications

| The material to be welded | Thickness/mm | Pre-weld condition | Electrode diameter/mm | Welding time/s | Electrode pressure/kN | Single-point shear strength/MPa | Forward tensile strength/MPa | |

| above | under | |||||||

| HastelloyX+HastelloyX | 1.0+1.0 | Solution or supply status | 6 | 7 | 0.16~0.24 | 0.1~0.2 | ≥9.35 | ≥6.36 |

| 1.5+1.5 | 6 | 7 | 0.20~0.36 | 0.2~0.3 | ≥12.30 | ≥10.60 | ||

(5) The mechanical properties of HastelloyX welded joints are shown in Table 5-5

and Table 5-5

| Welding method | Thickness /mm |

Pre-weld condition | Post-weld treatment | Welding wire grade | θ/℃ | Joint strength | Long-lasting performance | ||

| σb/MPa | Strength Coefficient/% | σ/MPa | t/h | ||||||

| TIG welding | 1.5 | Supply status | Not processed | HHastelloyX | 20 650 815 |

800 586 337 |

100 100 100 |

- 294 110 |

- 217.6 46.4 |

| Pulsed TIG welding | 1.0 | Supply status | Not processed | - | 20 650 |

842 531 |

100 90 |

- - |

- - |

| 1.5 | Supply status | Not processed | HSG-1 | 20 650 |

826 581 |

100 98 |

- 294 |

- 296.5 |

|

| Seam welding | 1.5 | Supply status | Not processed | - | 20 650 815 |

763 514 325 |

96 91 100 |

- 294 110 |

- 214.2 48.6 |

3. HastelloyX parts heat treatment process: solid solution treatment of plate parts: 1150 °C± 10 °C, 2~15min, fast air cooling. Welding parts or flame tube treatment: 980°C±10°C, 60min, air cooling. Stress relief treatment after machining: 870°C±10°C, 30~60min, air cooling. Stable size treatment of parts: 760°C±10°C, 2h, air cooling.

6. HastelloyX Variety Specifications and Supply Status:

1. Variety classification: HastelloyX seamless pipe, HastelloyX steel plate, HastelloyX round bar, HastelloyX forging, HastelloyX flange, HastelloyX ring, HastelloyX welded pipe, HastelloyX steel strip, HastelloyX wire and supporting welding consumables.

2. Delivery status: seamless tube: solid solution + acid white, length can be fixed; Plates: solid solution, pickling, trimming; Welded pipe: solid solution acid white + RT% flaw detection, forgings: annealing + polishing; The bar is in a forged state, the surface is polished or polished; The strip is delivered by cold rolling, solution soft state, and descaling; The filaments are delivered in solution pickled discs or straight strips, solution straight strips in finely polished condition.

Previous Page

C-263

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!