Product classification

Inconel 601

Inconel 601 (UNS N06601) is a nickel-based alloy with a chromium content of 21.0-25.09% and a nickel content of approximately 72%. This high-temperature nickel-based alloy exhibits strong oxidation resistance, high-temperature resistance, and corrosion resistance, and it also possesses high mechanical properties at elevated temperatures. Inconel 601 (UNS N06601) has high high-temperature strength, excellent oxidation resistance, and resistance to carbon and sulfur penetration. Particularly, it demonstrates outstanding resistance to oxidation spalling in environments with severe temperature fluctuations and repeated oxidation, making it widely used in various components of heat treatment furnaces, as well as in diesel automotive glow plug components.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

Inconel 601

Inconel 601

Material grade: Inconel 601 nickel-based alloy

National grade: UNS N06601

German grade: 2.4851

I. Overview of Inconel 601 (N06601) nickel-based alloy:

Inconel 601 (UNS N06601) is a high-temperature nickel-based alloy with a chromium content of 21.0-25.09% and a nickel content of about 72%. Inconel 601 (UNS N06601) has strong oxidation resistance, high-temperature resistance, and corrosion resistance, and it also has high mechanical properties at elevated temperatures. Inconel 601 (UNS N06601) has high-temperature strength and excellent oxidation resistance, carburization resistance, and sulfidation resistance. Especially in environments with severe temperature fluctuations and repeated oxidation, it exhibits excellent oxidation spall resistance, making it widely used in various components of heat treatment furnaces, diesel vehicle glow plug components, etc.

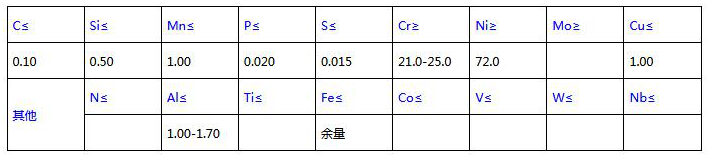

II. Chemical composition of Inconel 601 (N06601) nickel-based alloy: see Table 1-1:

1-1

III. Physical properties of Inconel 601 (N06601) nickel-based alloy (annealed):

1. Density of Inconel 601 (UNS N06601) nickel-based alloy: 8.42 g/cm3 (grams per cubic centimeter).

2. Elastic modulus of Inconel 601 (UNS N06601) nickel-based alloy: 124.7-206.5 GPa

3. Melting point of Inconel 601 (UNS N06601) nickel-based alloy: 1360-1411°C

4. Coefficient of thermal expansion of Inconel 601 (UNS N06601) nickel-based alloy (20 - 100°C): 13.75 μm/m °C

5. Specific heat of Inconel 601 (UNS N06601) nickel-based alloy: 451 J/kg-K

IV. Mechanical properties of Inconel 601 (N06601) nickel-based alloy:

1. Tensile strength (MPA): Rm N/mm2 ≥ 550

2. Yield strength (MPA): RP0.2 N/mm2 ≥ 205

3. Elongation: A5% ≥ 30

V. Processing and heat treatment of Inconel 601 (N06601) nickel-based alloy:

Inconel 601 (UNS N06601) nickel-based alloy does not belong to the category of precipitation hardening alloys, so it cannot be age-hardened through heat treatment. After cold working, when the temperature reaches around 900°C, the material softens. If high-temperature strength is required, it is recommended to perform solution heat treatment at temperatures of 1100 to 1200°C. The cooling method should use water cooling, and depending on the thickness of the plate, air cooling may also be used. However, to avoid carbide precipitation, it is recommended to cool as quickly as possible within the temperature range of 500 to 800°C.

VI. Formability of Inconel 601 (N06601) nickel-based alloy

Inconel 601 (UNS N06601) nickel-based alloy is relatively easy to process thermally. The heating temperature is 1150 to 1200°C, and the hot working temperature is 1050 to 1200°C. Simple processing can be done below 850°C. Cracking may occur in the temperature range of 650 to 850°C, so it is essential to avoid processing in this temperature range. Regarding cooling after hot working, to avoid carbide precipitation, it is recommended to increase the cooling rate within the range of 500 to 800°C. Alloy 601 has excellent cold workability and can be processed similarly to SUS 310S and Alloy 800.

VII. Varieties, specifications, and supply status of Inconel 601 (N06601) nickel-based alloy:

1. Variety classification: Inconel 601 seamless pipes, Inconel 601 steel plates, Inconel 601 round bars, Inconel 601 forgings, Inconel 601 flanges, Inconel 601 rings, Inconel 601 welded pipes, Inconel 601 steel strips, Inconel 601 wires, and matching welding materials.

2. Supply status: Seamless pipes: solution + acid pickling, length can be customized; plates: solution, acid washing, edge cutting; welded pipes: solution acid pickling + RT% flaw detection, forgings: annealed + turned; bars: in forged or rolled state, surface polished or turned; strips are cold-rolled. Solution soft state with deoxidized surface for delivery; wires are delivered in solution acid-washed coil or straight bar form, and solution straight bars are finely polished.

Previous Page

Next Page

Previous Page

Inconel 718

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!