Product classification

Gh4093

GH4093 is a nickel-based superalloy that exhibits excellent high-temperature strength, oxidation resistance, and corrosion resistance. Due to its outstanding performance, GH4093 is widely used in fields such as aviation, aerospace, energy, and chemical engineering.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

GH4093 is a nickel-based superalloy with excellent high-temperature strength, oxidation resistance, and corrosion resistance. Due to its outstanding performance, GH4093 is widely used in fields such as aviation, aerospace, energy, and chemical engineering.

Smelting Process

The smelting process of GH4093 is complex and refined, mainly including the following steps:

Vacuum Induction Melting (VIM)Under vacuum conditions, induction melting is performed, which effectively removes gases and impurities from the metal, improving the purity of the alloy.

Electroslag Remelting (ESR)Through the electroslag remelting process, the alloy can be further purified, improving its structure and performance, giving it superior high-temperature performance and stability.

Casting IngotThe melted alloy is cast into ingot form for subsequent processing and shaping.

Forging and Heat TreatmentThe cast ingot undergoes forging and heat treatment to improve the material's microstructure and enhance its mechanical properties.

Precision MachiningThrough precision machining processes, the alloy is shaped into the required forms and dimensions.

Application Fields

Due to its excellent performance, GH4093 has a wide range of applications in several fields:

AerospaceGH4093 is widely used in the manufacture of key components such as turbine blades, combustion chambers, and turbine discs for aircraft engines. These components operate under high temperature and pressure conditions, requiring materials with outstanding high-temperature strength and oxidation resistance.

Energy IndustryGH4093 is widely used in gas turbines, nuclear power plants, and fossil fuel power plants. Its high-temperature stability and corrosion resistance make it an ideal material for manufacturing high-temperature and high-pressure components.

Chemical IndustryIn chemical equipment, GH4093 is used to manufacture high-temperature and high-pressure reactors, heat exchangers, and evaporators. Its corrosion resistance and high-temperature strength allow it to perform excellently in harsh chemical environments.

Specific Parameters

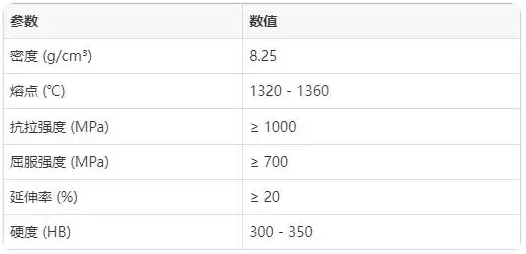

The specific parameters of the GH4093 alloy are shown in the table below:

Advantages

High High-Temperature StrengthGH4093 has extremely high strength in high-temperature environments, capable of withstanding harsh working conditions.

Excellent Oxidation and Corrosion ResistanceIn high-temperature and corrosive environments, GH4093 exhibits outstanding oxidation and corrosion resistance.

Good Thermal StabilityGH4093 has good thermal stability, able to maintain its mechanical properties over long periods in high-temperature environments.

Good MachinabilityGH4093 has excellent machinability, allowing it to be forged and precisely machined into various complex shapes.

Conclusion

As a high-performance nickel-based superalloy, GH4093, with its excellent high-temperature strength, oxidation resistance, and corrosion resistance, has been widely used in aviation, aerospace, energy, and chemical engineering. Its refined smelting process and excellent mechanical properties enable it to perform well in harsh working environments. Understanding the smelting process and applications of GH4093 helps to better leverage its role in various fields, providing strong material support for industrial technological advancement.

Previous Page

GH4090

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!