Product classification

NS312 corrosion-resistant alloy

NS312 (N06600, 2.4816) alloy is an early nickel-chromium-iron-based solution strengthened alloy, which has good high temperature corrosion resistance and oxidation resistance, excellent cold and hot working and welding process performance, and satisfactory thermal strength and high plasticity below 700 °C. The alloy can be strengthened by cold working, or it can be connected by resistance welding, fusion welding or brazing, and can be supplied with cold-rolled sheets, hot-rolled thick plates, strips, wires, bars, round cakes, ring blanks, ring forgings, etc., and is suitable for making oxidation resistant parts with low loads below 1100 °C.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

NS312

Material Grade: NS312 Corrosion Resistant Alloy

, USA Grade: UNS N06600

German Grade: W.Nr.2.4816

1. Overview of NS312 (N06600, 2.4816) corrosion-resistant alloys

NS312 (N06600, 2.4816) alloy is an early nickel-chromium-iron-based solution strengthened alloy, which has good high temperature corrosion resistance and oxidation resistance, excellent cold and hot working and welding process performance, and satisfactory thermal strength and high plasticity below 700 °C. The alloy can be strengthened by cold working, or it can be connected by resistance welding, fusion welding or brazing, and can be supplied with cold-rolled sheets, hot-rolled thick plates, strips, wires, bars, round cakes, ring blanks, ring forgings, etc., and is suitable for making oxidation resistant parts with low loads below 1100 °C.

1. NS312 (N06600, 2.4816) alloy material grade: NS312.

2. NS312 (N06600, 2.4816) alloy similar grades: Inconel600, GH600, GH3600 (China).

3. Technical standard for NS312 (N06600, 2.4816) alloy materials 4. Chemical composition of NS312 (N06600, 2.4816) alloy: see Table 1-1.

Table 1-1%.

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | Cu≤ |

| 0.15 | 0.50 | 1.00 | 0.040 | 0.015 | 14.0-17.0 | 72.0 | - | 0.50 |

| other | Al≤ | Ti≤ | Fe≤ | N≤ | Co≤ | Nb+Ta≤ | W≤ | V≤ |

| 0.35 | 0.50 | 6.0-10.0 | - | - | 1.00 | - | - |

Note: 1 The aerospace material standard BZ-44-9003B-0 stipulates that ω(C)≤0.10%, ω(P)≤0.020%, ω(Nb) ≤1.00%.

2 Fugaoxin 1995-13 standard stipulates that ω(P)≤0.025%, ω(Nb)≤1.00%.

5. NS312 (N06600, 2.4816) alloy heat treatment system: plate: 1010~1050°C, 3~5min/mm, air cooling; Strip: 1010°C±10°C, air-cooled; Wire: 1065°C±10°C, air cooled. The inspection test of bars and rings has been treated at 1010°C±10°C and air-cooled solid solution.

6. NS312 (N06600, 2.4816) alloy varieties and supply status: various specifications of plates, bars, forgings, strips, wires, round cakes, ring blanks, ring forgings can be supplied. Bars are supplied in a forged, surface-polished or turned finish; Round cakes and ring blanks are supplied in a forged state; Rings are supplied in a solid solution state; The plates are supplied after solid solution, alkali pickling, straightening and trimming; Strip is delivered by cold rolling, solution and descaling; The filaments are delivered in solution pickled discs or straight strips, solution straight strips in finely polished condition.

7. NS312 (N06600, 2.4816) alloy melting and casting process: the alloy is smelted by one of the following processes: (1) non-vacuum induction melting and electroslag remelting; (2) Electric arc furnace smelting and electroslag remelting; (3) Vacuum melting.

8. NS312 (N06600, 2.4816) alloy application overview and special requirements: the alloy has mature experience in foreign use, and has been made into aerospace engine parts in China, and has been used in aviation through flight tests.

2. Physical and chemical properties of NS312 (N06600, 2.4816) corrosion-resistant alloy:

1. NS312 (N06600, 2.4816) alloy thermal properties:

(1) NS312 melting temperature range: 1370~1430°C[1]。

(2) Thermal conductivity of NS312: see Table 2-1.

Table 2-1[2]

| θ/℃ | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| λ/(W/(m·℃)) | 12.85 | 13.94 | 15.15 | 16.62 | 18.71 | 20.72 | 22.40 | 24.49 | 27.00 | 29.51 | 31.60 |

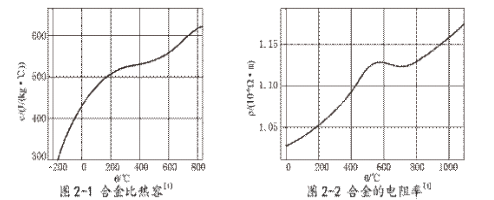

(3) Specific heat capacity of NS312: see Figure 2-1.

(4) NS312 line expansion coefficient: see Table 2-2.

2. NS312 (N06600, 2.4816) alloy density: ρ=8.43g/cm3。

3. Electrical properties of NS312 (N06600, 2.4816) alloy: the resistivity is shown in Figure 2-2

Table 2-2[2]

| θ/℃ | 20~200 | 20~300 | 20~400 | 20~500 | 20~600 | 20~700 | 20~800 | 20~1000 |

| α/10-6℃-1 | 12.35 | 12.75 | 13.10 | 13.55 | 14.50 | 15.15 | 15.70 | 16.20 |

4. NS312 (N06600, 2.4816) alloy magnetic properties: the alloy is non-magnetic.

5. NS312 (N06600, 2.4816) alloy chemical properties:

NS312 oxidation resistance: the oxidation rate tested in air medium for 100h is shown in Table 2-3.

Table 2-3[3]

| θ/℃ | 800 | 900 | 1000 |

| Oxidation rate/(g/m.)2·h) | 0.01865 | 0.05724 | 0.13718 |

3. Mechanical properties of NS312 (N06600, 2.4816) corrosion-resistant alloy: properties specified in NS312 technical standards: see Table 3-1.

Table 3-1

| variety | θ/℃ | Tensile properties | HBS | Flexure test | |||

| σb/MPa | σP0.2/MPa | δ5/% | φ/% | ||||

| Rods | 20 | ≥585 | ≥240 | ≥30 | - | 134~217 | - |

| Round cakes, rings or rings | 20 | ≥520 | ≥205 | ≥35 | - | ≥187 | - |

| Hot rolled plate | 20 | ≥550 | ≥240 | ≥35 | ≥40 | - | - |

| 900 | ≥95 | ≥45 | ≥40 | ≥50 | - | - | |

| Cold-rolled plate | 20 | ≥550 | ≥240 | ≥30 | - | - | ① |

| 900 | ≥90 | ≥40 | ≥60 | - | - | - | |

| Cold-rolled plate | 20 | ≥550 | ≥200 | ≥30 | - | - | Test |

| Strip | 20 | ≥550 | ≥240 | ≥30 | - | - | ① |

| Filament | 20 | Measured | Measured | Measured | - | HV≤151 | Cold top forging is qualified |

(1) The supply state plate should be tested at room temperature, the diameter of the mandrel is equal to the thickness of the product multiplied by the bending coefficient of Table 3-2, the bending axis should be parallel to the rolling direction, after bending 180°, check under magnification 20 times, and there shall be no cracks.

Table 3-2

| Product thickness/mm | <0.25 | 0.25~1.30 | >1.30~4.00 |

| Bending factor | Agreement of the Parties | 1 | 2 |

4. NS312 (N06600, 2.4816) corrosion-resistant alloy microstructure:

1. NS312 (N06600, 2.4816) alloy phase transformation temperature

2. NS312 (N06600, 2.4816) alloy time-temperature-microstructure transition curve,

3. NS312 (N06600, 2.4816) alloy microstructure: after 2h treatment at 1120 °C, the alloy only has TiN nitride and Cr7C Type 3 carbide is still Cr 7C3 and TiN in the microstructure after 1500h long-term aging at 870 °C, indicating that the microstructure of the alloy is stable.

5. Process performance and requirements of NS312 (N06600, 2.4816) corrosion-resistant alloy:

1. NS312 (N06600, 2.4816) alloy forming performance: the alloy has good hot working properties, and the heating temperature of ingot forging is 1110~1140 °C; The final forging temperature is not less than 950 °C, the slab rolling heating temperature is 1130~1170 °C, and the finishing rolling heating temperature is 1090~1130 °C. The solution treatment temperature of the finished product is 1010~1050°C.

2. NS312 (N06600, 2.4816) alloy welding performance: the alloy welding performance is good, and it can be connected by various methods such as arc welding, argon arc welding, resistance welding and brazing, and large or complex welded structural parts should be annealed at 870 °C for 1h after fusion welding to eliminate welding stress.

3. NS312 (N06600, 2.4816) alloy parts heat treatment process: the heat treatment process of parts should be carried out according to the heat treatment system of the corresponding material standards. The annealing of sheet and strip parts should be carried out in a protective atmosphere.

6. NS312 (N06600, 2.4816) corrosion-resistant alloy varieties and supply status

1. Variety classification: NS312 seamless pipe, NS312 steel plate, NS312 round bar, NS312 forging, NS312 flange, NS312 ring, NS312 welded pipe, NS312 steel belt, NS312 wire and supporting welding consumables.

2. Delivery status: seamless tube: solid solution + acid white, length can be fixed; Plates: solid solution, pickling, trimming; Welded pipe: solid solution acid white + RT% flaw detection, forgings: annealing + polishing; The bar is in a forged state, the surface is polished or polished; The strip is delivered by cold rolling, solution soft state, and descaling; The filaments are delivered in solution pickled discs or straight strips, solution straight strips in finely polished condition.

Previous Page

Next Page

Previous Page

NS336 corrosion-resistant alloy

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!