Product classification

NS111 corrosion-resistant alloy

NS111 (N08825, 2.4858 alloy) has the following characteristics: (1) Good resistance to stress corrosion cracking. (2) Good resistance to pitting and crevice corrosion. (3) Excellent oxidation resistance and non-oxidizing acidic performance. (4) Very good mechanical properties at room temperature and at high temperatures up to 550°C. (5) Certified for manufacturing pressure vessels at temperatures up to 450°C.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

NS111

Material grade: NS111 corrosion-resistant alloy

US grade: UNS N08825

German grade: W.Nr.2.4858

1.Overview of NS111 (N08825, 2.4858) corrosion-resistant alloy: NS111 (N08825, 2.4858) alloy is a fully austenitic nickel-iron-chromium alloy treated with titanium stabilization, and it contains copper and molybdenum.

1. NS111 (N08825, 2.4858) alloy has the following characteristics:

(1) Good stress corrosion cracking resistance.

(2) Good pitting and crevice corrosion resistance.

(3) Very good oxidation resistance and non-oxidizing acidic thermal performance.

(4) Good mechanical properties at room temperature and at high temperatures up to 550℃.

(5) Certified for manufacturing pressure vessels at temperatures up to 450℃.

2. Chemical composition of NS111 (N08825, 2.4858) alloy: %

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | Cu≤ |

| 0.025 | 0.50 | 1.00 | 0.020 | 0.010 | 19.5-23.5 | 38.0-46.0 | 2.5-3.5 | 1.5-3.0 |

| Others | Al≤ | Ti≤ | Fe≤ | N≤ | Co≤ | Nb≤ | W≤ | V≤ |

| 0.20 | 0.60-1.20 | Remainder | - | - | - | - | - |

3. Physical properties of NS111 (N08825, 2.4858) alloy:

(1) Density: ρ=8.1g/cm3

(2) Melting temperature range: 1370~1400℃

| Temperature ℃ | Specific heat J/Kg K | Thermal conductivity W/mK | Electrical resistivity μΩcm | Elastic modulus KN/mm2 | Thermal expansion coefficient 10-6/K |

| 20 | 440 | 10.8 | 112 | 195 | |

| 93 | |||||

| 100 | 462 | 12.4 | 114 | 190 | 14.1 |

| 200 | 488 | 14.1 | 118 | 185 | 14.9 |

| 204 | |||||

| 300 | 514 | 15.6 | 120 | 179 | 15.2 |

| 316 | |||||

| 400 | 540 | 16.9 | 124 | 174 | 15.6 |

| 427 | |||||

| 500 | 565 | 18.3 | 126 | 168 | 15.8 |

| 538 | |||||

| 600 | 590 | 19.6 | 126 | 161 | 16.0 |

| 649 | |||||

| 700 | 615 | 21.0 | 127 | 154 | 16.7 |

| 760 | |||||

| 800 | 655 | 23.2 | 128 | 142 | 17.2 |

| 871 | |||||

| 900 | 680 | 25.7 | 129 | 130 | 17.6 |

| 982 | |||||

| 1000 | 710 | 28.1 | 130 | 119 | 17.9 |

4. Mechanical properties of NS111 (N08825, 2.4858) alloy:

The properties listed in the table below apply to specified products of NS111 alloy after softening annealing (stabilization annealing). Special properties for non-standard size materials can be provided according to specific application requirements.

Room temperature mechanical properties (minimum values)

| Product | Specification | Yield strength RP0.2N/mm2 |

Yield strength RP1.0N/mm2 |

Tensile strength RmN/mm2 |

Elongation A50% |

Brinell hardness HB |

| Thin plate strip/cold rolled Plate/hot rolled |

0.5-6.4 | 240 | 265 | 585 | 30 | <=200 |

| 5-100 | 135-165 | |||||

| Bar Cold working Hot working |

1.6-64 | |||||

| 25-100 | ||||||

| >100-240 | 220 | 250 | 550 | 35 | ||

| Pipe Cold working Hot working |

64-240 | 180 | - | 530 | 30 | - |

| 5-100 | 240 | 265 | 585 | 30 | ||

| Condensers and heat exchangers | 16-76 |

High temperature mechanical properties (minimum values)

| Product | Yield strength RP0.2N/mm2 | Yield strength RP1.0N/mm2 | ||||||||||

| Temperature ℃ | 100 | 200 | 300 | 400 | 450 | 100 | 200 | 300 | 400 | 450 | ||

| Plate, strip, pipe | 205 | 180 | 170 | 160 | 155 | 235 | 205 | 195 | 185 | 180 | ||

| Bar | 190 | 165 | 155 | 145 | 140 | 220 | 190 | 180 | 170 | 165 | ||

5. ISO V-notch impact test of NS111 (N08825, 2.4858) alloy:

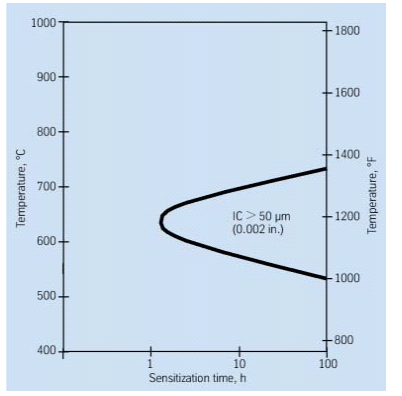

Room temperature average: axial >=150J/cm2, radial >=100J/cm2 , Time-Temperature-Sensitization curve.

6. Condition stress values of NS111 (N08825, 2.4858) alloy:

High condition stress values reaching 90% yield strength can be applied to applications allowing slightly larger deformation. The permanent stresses caused by these stresses can lead to dimensional changes, so they are not recommended for flange and gasket connections.

7. NS111 (N08825, 2.4858) alloy metallographic structure:

The NS111 alloy has a stable face-centered cubic structure. The chemical composition and appropriate heat treatment ensure that corrosion resistance is not weakened by sensitization.

8. NS111 (N08825, 2.4858) alloy corrosion resistance:

NS111 is a general-purpose engineering alloy that exhibits resistance to acid and alkali metal corrosion in both oxidizing and reducing environments. The high nickel content gives the alloy effective resistance to stress corrosion cracking. Its corrosion resistance is excellent in various media, such as sulfuric acid, phosphoric acid, nitric acid, and organic acids, as well as alkali metals like sodium hydroxide, potassium hydroxide, and hydrochloric acid solutions. The high overall performance of NS111 is evident in the diverse corrosive media of nuclear fuel dissolution systems, where sulfuric acid, nitric acid, and sodium hydroxide are processed in the same equipment.

II.NS111 (N08825, 2.4858) corrosion-resistant alloy application range: NS111 is widely used in various industrial fields with operating temperatures not exceeding 550°C. Typical applications include:

1. Heating pipes, containers, baskets, and chains used in sulfuric acid pickling plants.

2. Seawater cooling heat exchangers, marine product pipeline systems, and pipelines in acidic gas environments.

3. Heat exchangers, evaporators, washing, and immersion pipes in phosphoric acid production.

4. Air heat exchangers in petroleum refining.

5. Food engineering.

6. Chemical processes.

7. Flame-retardant alloys for high-pressure oxygen applications.

III.NS111 (N08825, 2.4858) corrosion-resistant alloy processing and heat treatment: The NS111 alloy is easy to process in general industrial processes.

1. NS111 (N08825, 2.4858) alloy preheating:

Temperature control is crucial to ensure that the alloy's corrosion resistance is not weakened by sensitization. The workpiece must be surface cleaned before and during heating to maintain a clean surface. If the heating environment contains sulfur, phosphorus, lead, or other low-melting-point metals, the Nicrofer 6023/6023H alloy will become brittle. Impurities can come from marking paints, chalk, lubricants, water, fuels, etc. The sulfur content in fuels should be low; for liquefied gas and natural gas, the impurity content should be below 0.1%, for city gas below 0.25g/m3, and for petroleum gas below 0.5% is ideal.

Heat treatment is best conducted in a vacuum resistance furnace or an inert gas protective atmosphere, as this allows for precise temperature control and avoids contamination from impurities. If the gas has low impurity content, a gas heating furnace may also be considered, which can provide a neutral or weakly oxidizing atmosphere. Fluctuations in the gas composition between oxidizing and reducing should be avoided, and the combustion flame should not be directed at the workpiece.

2. NS111 (N08825, 2.4858) alloy hot processing:

The suitable hot processing temperature for NS111 alloy is 1150-900°C, and the cooling method can be water quenching or rapid air cooling. During hot processing, the workpiece can be directly placed into a preheated furnace. After the furnace reaches temperature, the holding time for the material is 60 minutes for every 100mm thickness. After holding for the specified time, it should be removed from the furnace and processed within the specified temperature range. If the metal temperature drops below the minimum processing temperature, it should be reheated. After hot processing, it should be promptly annealed to ensure optimal corrosion resistance and suitable crystal structure.

3. NS111 (N08825, 2.4858) alloy cold processing:

Cold processing should be carried out after solution treatment. The work hardening rate of NS111 is close to that of austenitic stainless steel, so the processing equipment should be adjusted accordingly.

When the amount of cold processing is large, an intermediate annealing process should be included. When the final cold deformation exceeds 15%, final stabilization treatment is required.

4. NS111 (N08825, 2.4858) alloy heat treatment:

The temperature range for softening annealing or stabilization treatment is 920-980°C, with the most suitable being 940±10°C. For workpieces thicker than 1.5mm, water quenching or rapid air cooling is recommended to achieve maximum creep resistance.

During any heat treatment process, attention should be paid to the cleanliness issues mentioned earlier.

5. NS111 (N08825, 2.4858) alloy grinding and pickling:

Oxides near the welds of NS111 workpieces are more difficult to remove than those on stainless steel and require grinding with fine sand belts or grinding wheels. Care should be taken during grinding to maintain the metal's luster. Before pickling in a mixed acid of nitric acid and hydrofluoric acid, oxides should also be removed with sandpaper or pre-treated in a salt bath. The pickling time should be especially noted.

6. NS111 (N08825, 2.4858) alloy machining:

Machining of NS111 should be carried out after solution treatment, taking into account the material's work hardening characteristics. Unlike austenitic stainless steel, it requires low surface cutting speeds and heavy feed rates.

7. NS111 (N08825, 2.4858) alloy welding: When welding nickel-based alloys, the following procedures should be followed:

(1) Work area

The work area should be separated or have sufficient distance from the carbon steel processing area, kept as clean as possible, with partitions and avoiding ventilation between the two areas.

(2) Work clothing and auxiliary supplies

Clean fine-textured leather gloves should be worn, and clean work clothing should be worn.

Previous Page

Next Page

Previous Page

NS334 corrosion-resistant alloy

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!