Product classification

High temperature alloy GH2747 wire/plate/bar

GH2747 is a high temperature alloy which can withstand higher use temperature of the Fe-Ni-Cr deposition hardening deformation of high temperature alloy, the old brand GH747. The GH2747 in the solid solution state can be used for a long time at 1100-1250 ℃, and the short-term use temperature is 1300 ℃. And the welding performance is good, GH2747 has high strength, good organizational stability, high temperature environment has good oxidation and corrosion resistance.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

GH2747 Wire/Plate/Bar/Tube/Bar

Brief Introduction of 1. GH2747 Material

GH2747 is a high temperature alloy which can withstand higher use temperature of the Fe-Ni-Cr deposition hardening deformation of high temperature alloy, the old brand GH747. The GH2747 in the solid solution state can be used for a long time at 1100-1250 ℃, and the short-term use temperature is 1300 ℃. And the welding performance is good, GH2747 has high strength, good organizational stability, high temperature environment has good oxidation and corrosion resistance.

2. GH2747 executive standard

GB/T14992-2005-Classification and designation of high-temperature alloys and intermetallic compounds

Q/GYB511 GH2747 Alloy Hot Rolled and Forged Bars

Q/GYB511 "GH2747 alloy cold drawn (rolled) seamless tube"

GB/T15062 "general purpose high temperature alloy tube"

GJB1952A Specification for Cold Rolled Sheet of Superalloys for Aviation

GJB2297A Specification for Cold Drawn (Rolled) Seamless Tubes of High Temperature Alloys for Aviation

GJB2612 Specification for Cold-Drawn Materials of High-Temperature Alloys for Welding

GJB3165A Specification for Hot Rolled and Forged High Temperature Alloy Bars for Aero-Bearing Parts

GJB3317A Specification for Hot Rolled Plates of Aviation Superalloys

GJB3318A Specification for Hot Rolled Strip of Aviation Superalloys

HB/Z140 Aviation High Temperature Alloy Heat Treatment Process

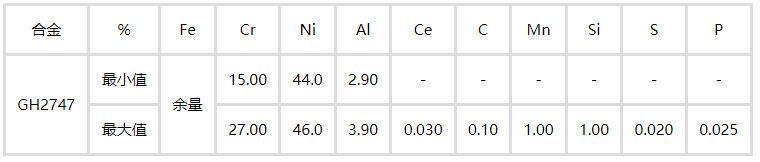

3. GH2747 Chemical Composition

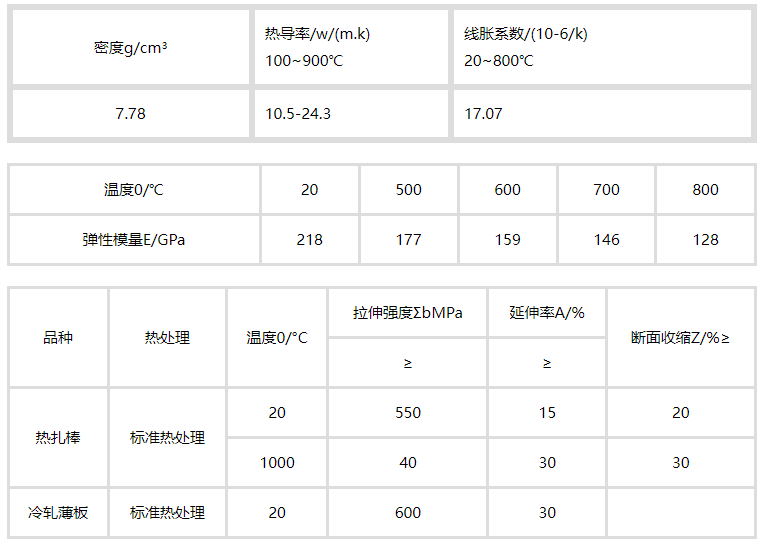

4. physical properties

5. welding performance

The alloy has satisfactory welding process performance, and all welding methods can be used for welding. Argon arc welding, spot welding, seam welding and electron beam welding have excellent welding effects. When welding with dissimilar materials, the base metal wire can be used as the filling material, and the same type of alloy can also be used as the filling material.

6. Application Areas

GH2747 is widely used in nuclear energy, petrochemical, metallurgy and other fields of high temperature oxidation resistance equipment parts.

Previous Page

Next Page

Previous Page

High temperature alloy tape GH3600

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!