Product classification

Inconel 625

Inconel 625 is a nickel-based high-temperature alloy that is solid-solution strengthened with molybdenum and niobium as the main strengthening elements. It has excellent corrosion resistance and oxidation resistance, good tensile properties and fatigue properties from low temperatures up to 980°C, and is resistant to stress corrosion in salt spray environments. Therefore, it can be widely used in the manufacture of aircraft engine components, aerospace structural components, and chemical equipment. The alloy has good processing and welding properties and is available in various forms such as plates, bars, pipes, wires, strips, and forgings.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

Inconel 625

Commercial grade: Inconel 625 nickel-based high-temperature alloy

US grade: UNS N06625

National grade: GH3625/GH625

French grade: NC22DNb

German grade: W.Nr.2.4856

1. Overview of Inconel 625 (NO6625) high-temperature alloy:

Inconel 625 is a nickel-based high-temperature alloy with solid solution strengthening, primarily reinforced by molybdenum and niobium. It has excellent corrosion resistance and oxidation resistance, good tensile and fatigue properties from low temperatures up to 980°C, and resistance to stress corrosion in salt mist atmospheres. Therefore, it can be widely used in the manufacture of aircraft engine components, aerospace structural parts, and chemical equipment. The alloy has good processing and welding properties and can be supplied in various forms such as plates, bars, pipes, wires, strips, and forgings.

1. Material grade: Inconel 625.

2. Similar grades to Inconel 625: GH3625 (GH625 in China), UNS N06625 (USA), NC22DNb (France), 2.4856 (Germany).

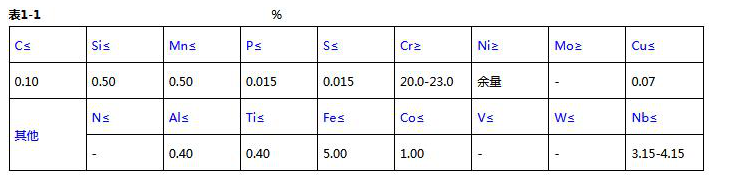

3. Chemical composition: See Table 1-1.

4. Heat treatment system: Bars: 950~1030°C, air cooling or water cooling; or 1090~1200°C, air cooling or water cooling solid solution treatment. Plates: 950~1030°C, air cooling; or 1090~1200°C air cooling. Pipes: Recommended annealing temperature: 960~1030°C, air cooling or water cooling.

5. Variety specifications and supply status: Bars with a diameter of 25~80mm and plates with a thickness of 80.8~10.5mm can be supplied, as well as seamless (welded) pipes with a diameter of 6~40mm. Bars are delivered in a turned or polished state without heat treatment; plates are supplied after solid solution and finishing; pipes are supplied after solid solution and acid pickling (or bright annealing).

6. Melting and casting process: The alloy is produced using vacuum induction melting followed by electroslag remelting or vacuum arc remelting.

7. Application overview and special requirements: This alloy is used to manufacture engine casings, guide blades, mounting edges, and fuel manifolds, and has passed practical application assessments. The maximum operating temperature is 950°C; the alloy exhibits some aging hardening after long-term use at 550~700°C, leading to a decrease in alloy plasticity.

2. Physical and chemical properties of Inconel 625 (N06625) high-temperature alloy:

1. Thermal properties

(1). Melting temperature range of Inconel 625: 1290~1350°C

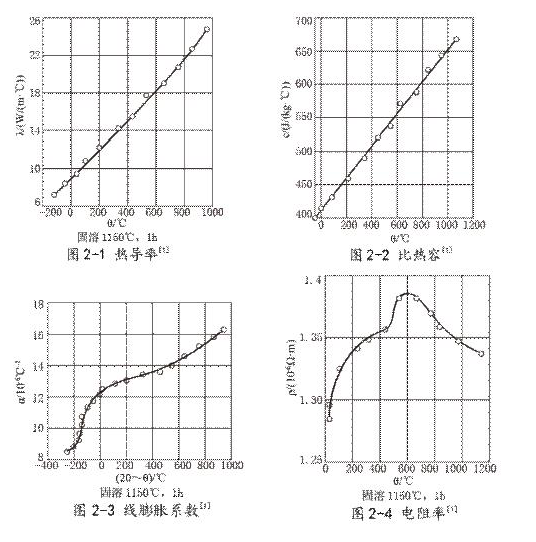

(2). Thermal conductivity: See Figure 2-1.

(3). Specific heat capacity: See Figure 2-2.

(4). Coefficient of linear expansion: See Figure 2-3.

2. Density of Inconel 625: p=8.44g/cm3

3. Electrical properties of Inconel 625: Alloy resistivity is shown in Figure 2-4.

4. Magnetic properties of Inconel 625: The alloy is non-magnetic.

5. Chemical properties of Inconel 625:

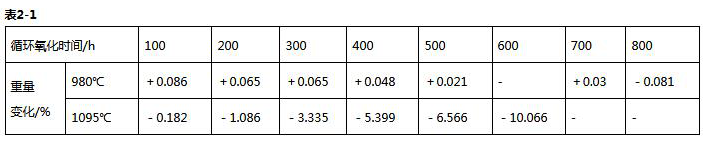

(1) Oxidation resistance of Inconel 625: The alloy has excellent high-temperature oxidation resistance. The weight change of the alloy after cyclic oxidation in air at high temperatures is shown in Table 2-1.

Note: Cyclic oxidation involves heating for 15 minutes and cooling for 5 minutes.

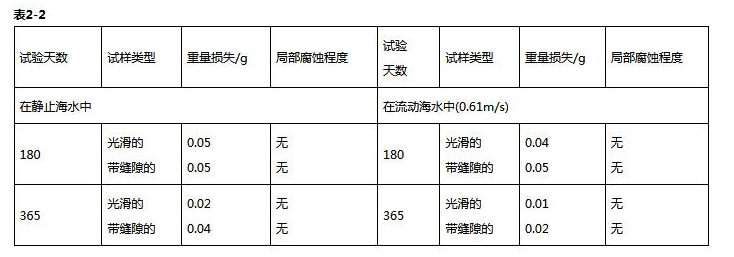

(2) Corrosion resistance of Inconel 625: The alloy has good resistance to seawater corrosion, as shown in Table 2-2. The alloy also resists various salt solutions. Additionally, it has good resistance to nitric acid and phosphoric acid corrosion, and considerable resistance to hydrochloric acid below boiling point and low concentration sulfuric acid.

Note: Smooth samples refer to flat samples with circular welds measuring 6.4mm x 100mm x 300mm, which are annealed at 980°C before welding. Gap samples refer to those fixed at the center of the plate surface with a 32mm fiber gasket using bolts.

3. Mechanical properties of Inconel 625 (NO6625) high-temperature alloy:

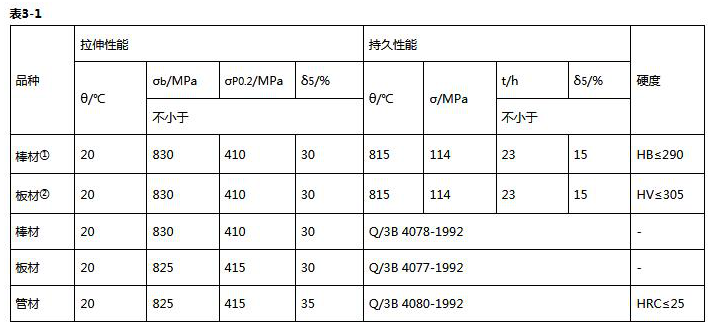

The performance specified by the technical standards for Inconel 625: See Table 3-1.

① Standard: Z9-0105-1990 ② Standards Z9-0104-1990 and GJB-3317-1998

4. Variety specifications and supply status of Inconel 625 (N06625) high-temperature alloy:

1. Classification: Inconel 625 seamless pipes, Inconel 625 steel plates, Inconel 625 round steel, Inconel 625 forgings, Inconel 625 flanges, Inconel 625 rings, Inconel 625 welded pipes, Inconel 625 steel strips, Inconel 625 wires, and matching welding materials.

2. Supply status: Seamless pipes: solid solution + acid pickling, length can be customized; plates: solid solution, acid pickling, trimmed; welded pipes: solid solution acid pickling + RT% flaw detection, forgings: annealed + turned; bars in forged state, surface polished or turned; strips delivered after cold rolling, solid solution soft state, and descaling; wires delivered in solid solution acid pickled coil or straight bar form, solid solution straight bar finely polished.

Previous Page

Next Page

Previous Page

None

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!