Product classification

Inconel 600

Inconel 600 is an early-developed nickel-chromium-iron-based solid solution strengthened alloy, which has good high-temperature corrosion resistance and oxidation resistance, excellent cold and hot processing and welding process performance, and satisfactory thermal strength and high plasticity below 700°C. The alloy can be strengthened through cold working and can be joined using resistance welding, fusion welding, or brazing. It is available in forms such as cold-rolled thin plates, hot-rolled thick plates, strips, wires, bars, discs, rings, and ring forgings, making it suitable for manufacturing oxidation-resistant parts that bear low loads at temperatures below 1100°C.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

Inconel 600

Commercial grade: Inconel 600 nickel-based high-temperature alloy

US grade: N06600 nickel-based high-temperature alloy

Chinese grade: GH600/GH3600

1. Overview of Inconel 600 (N06600) nickel-based alloy:

Inconel 600 is an early developed nickel-chromium-iron-based solid solution strengthened alloy, which has good high-temperature corrosion resistance and oxidation resistance, excellent cold and hot processing and welding process performance, and satisfactory thermal strength and high plasticity below 700°C. The alloy can be strengthened by cold working and can be connected by resistance welding, fusion welding, or brazing. It can be supplied in cold-rolled thin plates, hot-rolled thick plates, strips, wires, bars, discs, ring blanks, and ring forgings, suitable for making oxidation-resistant parts that bear low loads below 1100°C.

1. Material grade: Inconel 600 (N06600) nickel-based alloy.

2. Similar grades to Inconel 600: Inconel, GH600, GH3600 (China)

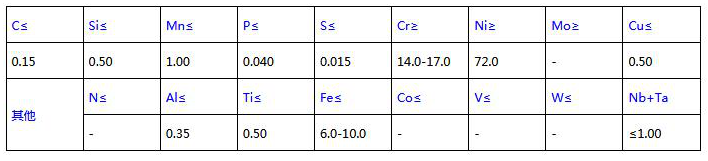

3. Chemical composition of Inconel 600: see Table 1-1.

1-1

Note: 1. The aerospace material standard BZ 44-9003B-0 specifies w(C) ≤ 0.10%, w(P) ≤ 0.020%, w(Nb) ≤ 1.00%.

2. The Fuhai New 1995-13 standard specifies w(P) ≤ 0.025%, w(Nb) ≤ 1.00%.

3. Heat treatment system: Plates: 1010~ 1050°C, 3~ 5 min/mm, air cooling; bars: 1010°C + 10°C, air cooling; wires: 1065°C + 10°C, air cooling. Bars and ring parts are inspected and tested at 1010°C + 10°C, air-cooled solid solution treatment.

4. Variety specifications and supply status: Various specifications of plates, bars, forgings, strips, wires, discs, ring blanks, and ring forgings can be supplied. Bars are supplied in a forged and rolled state with a polished or turned surface; discs and ring blanks are supplied in a forged state; ring parts are supplied in a solid solution state; plates are supplied after solid solution, alkaline acid washing, straightening, and edge cutting; bars are supplied after cold rolling. Solid solution, decarburization skin delivery; wires are supplied in solid solution acid-washed coil or straight bar form, solid solution straight bars finely polished.

5. Melting and casting process: The alloy is melted using one of the following processes: non-vacuum induction melting plus electroslag remelting; electric arc furnace melting plus electroslag remelting; vacuum melting.

6. Application overview and special requirements: This alloy has mature usage experience abroad, and has been made into aerospace engine components domestically, passing flight tests, and is also starting to be used in aviation.

2. Physical and chemical properties of Inconel 600 (N06600) nickel-based alloy:

1. Thermal properties of Inconel 600:

(1). Melting temperature range: 1370~ 1430°C.

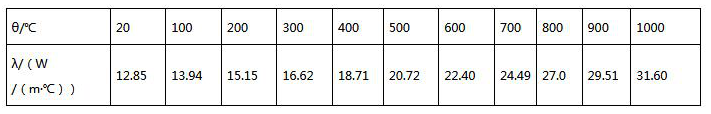

(2). Thermal conductivity: see Table 2-1

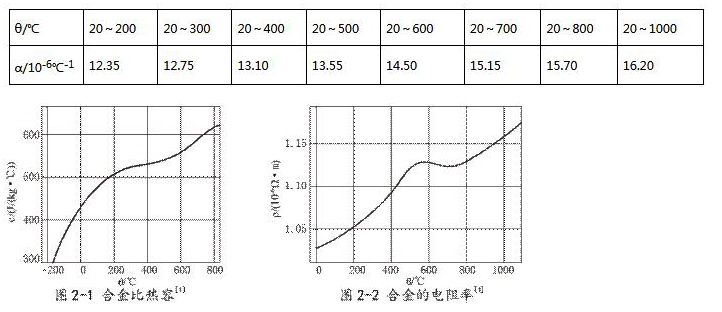

(3). Specific heat capacity: see Figure 2-1

(4). Linear expansion coefficient: see Table 2-2

2. Density of Inconel 600: p = 8.43 g/cm³

3. Electrical properties of Inconel 600: resistivity see Figure 2-2

4. Magnetic properties of Inconel 600: the alloy is non-magnetic

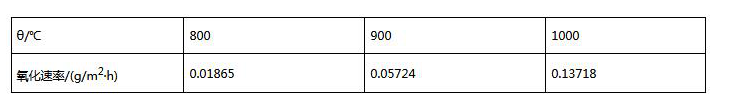

5. Chemical properties of Inconel 600: oxidation resistance: oxidation rate after 100 hours of testing in air medium see Table 2-3

2-1

2-2

2-3

3. Mechanical properties of Inconel 600 (N06600) nickel-based alloy:

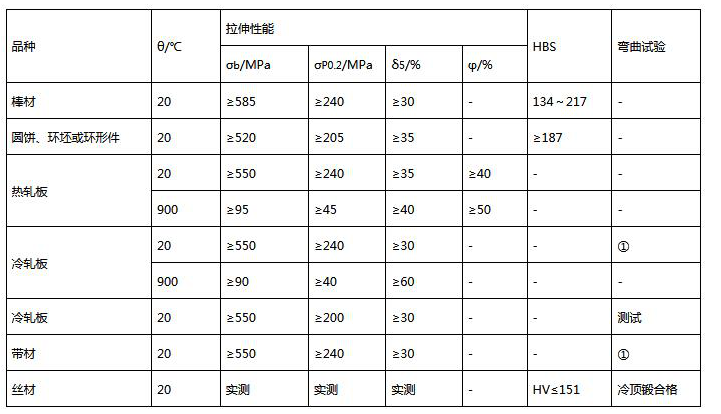

The performance specified by the technical standards of Inconel 600: see Table 3-1.

3-1

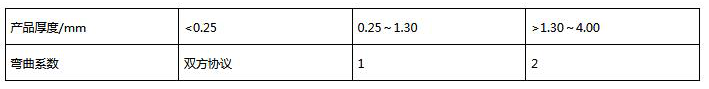

Note: The supplied state plates should undergo room temperature bending tests, with the core rod diameter equal to the thickness multiplied by the bending coefficient in Table 3-2, and the bending axis should be parallel to the rolling direction. After bending 180 degrees, it should be inspected under 20x magnification, and no cracks should be present.

Table 3-2

4. Application fields of Inconel 600 (N06600):

1. Thermocouple sheaths in corrosive atmospheres

2. Production of vinyl chloride monomer: resistant to chlorine gas, hydrogen chloride, oxidation, and carbonization corrosion

3. Uranium oxidation conversion to hexafluoride: resistant to hydrofluoric acid corrosion

4. Production and use fields of corrosive alkali metals, especially in environments using sulfides

5. Production of titanium dioxide by chlorine method

6. Production of organic or inorganic chlorides and fluorides: resistant to chlorine gas and fluorine gas corrosion

7. Nuclear reactors

8. Bottles and components in heat treatment furnaces, especially in carbonization and nitriding atmospheres

9. In petrochemical production, the catalytic regenerators are recommended to use alloy 600H for applications above 700°C to achieve a longer service life.

5. Process performance and requirements of Inconel 600 (N06600) nickel-based alloy:

1. Inconel 600 forming performance: The alloy has good hot working performance, with the forging heating temperature of steel ingots being 1110~1140°C; the final forging temperature should not exceed 950°C, the heating temperature for slab rolling is 1130~1170°C, the heating temperature for finish rolling is 1090~1130°C, and the solution treatment temperature for finished products is 1010~1050°C.

2. Inconel 600 welding performance: The welding performance is good, and various methods such as arc welding, argon arc welding, resistance welding, and brazing can be used for connection. Large or complex welded structures should be annealed at 870°C for 1 hour after fusion welding to eliminate welding stress.

3. Inconel 600 parts heat treatment process: The heat treatment process of the parts should be carried out according to the heat treatment system of the corresponding material standards. The annealing treatment of thin plates and strips should be conducted in a protective atmosphere.

6. Inconel 600 (N06600) nickel-based alloy varieties, specifications, and supply status:

1. Variety classification: Inconel 600 seamless pipes, Inconel 600 steel plates, Inconel 600 round bars, Inconel 600 forgings, Inconel 600 flanges, Inconel 600 rings, Inconel 600 welded pipes, Inconel 600 steel strips, Inconel 600 wires, and Inconel 600 matching welding materials.

2. Supply status: Seamless pipes: solution + acid pickling, length can be customized; plates: solution, acid pickling, trimmed edges; welded pipes: solution acid pickling + RT% flaw detection, forgings: annealed + turned; bars in forged and rolled state, surface polished or turned; strips delivered after cold rolling, solution soft state, and descaling; wires delivered in solution acid pickled coil or straight bar form. Solution straight bars are delivered in fine polished state.

Next Page

Previous Page

Inconel 601

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!