Product classification

Hastelloy C-4

Hastelloy C-4 (N06455) is an austenitic low-carbon nickel-molybdenum-chromium alloy. The main difference between it and similar alloys with earlier developed chemical compositions, such as Nicrofer 6616hMo, is the lower content of carbon, silicon, iron, and tungsten. This chemical composition provides excellent stability at temperatures ranging from 650 to 1040°C, enhances resistance to intergranular corrosion, and can avoid edge line corrosion sensitivity and corrosion in the heat-affected zone of welds under appropriate manufacturing conditions.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

Hastelloy C4

Material grade: Hastelloy C-4

US grade: UNS N06455

German grade: W.Nr.2.4610

1.Overview of Hastelloy C-4 (N06455):

Hastelloy C-4 (N06455) is an austenitic low-carbon nickel-molybdenum-chromium alloy. The main difference from Nicrofer 6616hMo and other early developed alloys with similar chemical compositions is the low carbon, silicon, iron, and tungsten content. This chemical composition provides excellent stability at 650-1040℃, enhances resistance to intergranular corrosion, and can avoid edge line corrosion sensitivity and weld heat-affected zone corrosion under appropriate manufacturing conditions.

1. Characteristics of Hastelloy C-4 (N06455):

(1) Excellent corrosion resistance to most corrosive media, especially in reducing conditions.

(2) Excellent resistance to localized corrosion in halides.

2. Chemical composition of Hastelloy C-4 (N06455): %

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | Cu≤ |

| 0.09 | 0.5 | 1.00 | 0.035 | 0.030 | 14.5-17.5 | Balance | 14.0-17.0 | - |

| Others | N≤ | Al≤ | Ti≤ | Fe≤ | Co≤ | V≤ | W≤ | Nb≤ |

| - | - | 0.70 | 3.00 | 2.00 | - | - | - |

3. Physical properties of Hastelloy C-4 (N06455):

(1) Density of Hastelloy C-4 (N06455): ρ=8.6g/cm3,

(2) Melting temperature range of Hastelloy C-4 (N06455): 1335~1380℃.

| Temperature (℃) | Specific heat capacity (J/Kg K) | Thermal conductivity (W/m K) | Resistivity (μΩcm) | Elastic modulus (KN/mm2) | Expansion coefficient (10-6/K) |

| 0 | 406 | ||||

| 20 | 408 | 10.1 | 124 | 211 | |

| 93 | |||||

| 100 | 426 | 11.4 | 125 | 207 | 10.9 |

| 200 | 448 | 13.2 | 126 | 202 | 11.9 |

| 204 | |||||

| 300 | 465 | 15.0 | 127 | 195 | 12.5 |

| 316 | |||||

| 400 | 477 | 16.7 | 128 | 188 | 12.9 |

| 427 | |||||

| 500 | 490 | 18.4 | 129 | 181 | 13.2 |

| 538 | |||||

| 600 | 502 | 20.5 | 132 | 175 | 13.6 |

| 649 | |||||

| 700 | 512 | 22.6 | 135 | 168 | 14.0 |

| 760 | |||||

| 800 | 522 | 24.8 | 138 | 158 | 14.5 |

| 871 | |||||

| 900 | 149 | 15.1 | |||

| 982 | |||||

| 1000 | 138 | 15.9 |

4. Mechanical properties of Hastelloy C-4 (N06455):

The minimum values in the table are measured data in the longitudinal and transverse directions of the calibrated size specification sample (solution-treated state). Special specification products and special material properties can be customized according to customer requirements.

Hastelloy C-4: ISO-V notch test: average value ≥120J/cm2 (room temperature), ≥120J/cm2 (-196℃).

5. Metallographic structure of Hastelloy C-4 (N06455):

Hastelloy C-4 has a face-centered cubic lattice structure, and its chemical composition ensures metallographic stability and resistance to sensitization.

6. Corrosion resistance of Hastelloy C-4 (N06455):

The high molybdenum and chromium content allows Hastelloy C-4 alloy to resist the erosion of various chemical media, including reducing media such as phosphoric acid, hydrochloric acid, sulfuric acid, chlorine gas, and organic or inorganic chlorine-containing media. Due to its high nickel content, Hastelloy C-4 can effectively resist stress corrosion cracking caused by chlorine, even in hot chloride solutions.

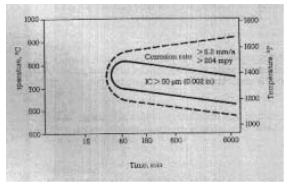

Time-temperature-sensitization curve (carbon content 0.008%, reference ASTM G28 Method A)

2.Machinability of Hastelloy C-4 (N06455):

1. Machining and heat treatment of Hastelloy C-4: Hastelloy C-4 alloy can be manufactured and processed using traditional production processes.

2. Heating of Hastelloy C-4: The workpiece should always be kept clean and uncontaminated before and during heat treatment.

During heat treatment, it should not come into contact with sulfur, phosphorus, lead, and other low-melting-point metals; otherwise, Nicrofer 6616 hMo alloy will become brittle. Care should be taken to remove contaminants such as marking paint, temperature indicating paint, colored crayons, lubricants, and fuels.

The lower the sulfur content in the fuel, the better; the sulfur content in natural gas should be less than 0.1%, and in heavy oil, it should be less than 0.5%. Electric furnace heating is the best choice because it can control the temperature precisely, and the furnace gas is clean. If the gas from a gas furnace is sufficiently pure, it can also be chosen. The furnace gas for heating should be neutral to slightly reducing, and fluctuations between oxidizing and reducing conditions should be avoided; the heating flame should not be directed at the workpiece.

3. Hot working of Hastelloy C-4: The hot working temperature range for Hastelloy C-4 is 1080℃ to 900℃, with cooling methods being water cooling or other rapid cooling methods. To ensure optimal corrosion resistance, solution heat treatment should be performed after hot working.

4. Hastelloy C-4 cold working: The workpiece should be in a solution heat-treated state during cold working. The work hardening rate of Hastelloy C-4 is greater than that of austenitic stainless steel, so it is necessary to select processing equipment accordingly. Intermediate annealing should be performed during the cold rolling process. If the cold rolling deformation exceeds 15%, a secondary solution treatment is required for the workpiece.

5. Hastelloy C-4 heat treatment: The solution treatment temperature range for Hastelloy C-4 is 1050°C to 1100°C. For materials with a thickness of less than 1.5mm, water quenching is recommended, and rapid air cooling can also be used to achieve maximum corrosion resistance. The workpiece must be kept clean during the heat treatment process.

6. Hastelloy C-4 oxide scale: The adhesion of surface oxides and slag around the weld of Hastelloy C-4 is stronger than that of stainless steel. It is recommended to use fine-grained sand belts or fine-grained grinding wheels for polishing. Before pickling with HNO3/HF mixed acid, sandblasting or grinding must be done to break the oxide film.

7. Hastelloy C-4 machining: Machining of Hastelloy C-4 should be done in the annealed state. Due to the high work hardening of Nicrofer 6616 hMo, low cutting speeds and heavy feed should be used to machine below the cold-work-hardened surface.

8. Hastelloy C-4 welding: Hastelloy C-4 can be welded using various welding processes, such as tungsten electrode inert gas shielded welding, plasma arc welding, manual submerged arc welding, metal inert gas shielded welding, and flux-cored inert gas shielded welding. Pulsed arc welding is preferred.

Before welding, the material should be in the annealed state, and oxide scale, oil stains, and various markings should be removed. The area about 25mm wide on both sides of the weld seam should be polished to a bright metal surface. Low heat input should be used, with interlayer temperatures not exceeding 150°C. This steel type does not require pre-weld and post-weld heat treatment. Recommended filler metals: welding wire: ERNiCrMo-7, welding rod: ENiCrMo-7.

To achieve the best corrosion resistance, argon arc welding (GTAW) should be considered first. Use filler materials that are consistent with the base material for GTAW and SMAW.

Three,Application range of Hastelloy C-4:

Hastelloy C-4 has been widely used in most chemical fields and high-temperature environments.

Typical application areas: flue gas desulfurization systems, pickling and acid regeneration plants, acetic acid and agricultural chemical production, titanium dioxide production (chlorination method), and de-electroplating, etc.

Four,Varieties, specifications, and supply status of Hastelloy C-4:

1. Variety classification: Hastelloy C-4 seamless pipes, Hastelloy C-4 steel plates, Hastelloy C-4 round bars, Hastelloy C-4 forgings, Hastelloy C-4 flanges, Hastelloy C-4 rings, Hastelloy C-4 welded pipes, Hastelloy C-4 steel strips, Hastelloy C-4 wires, and matching welding materials.

2. Delivery status: Seamless pipes: solution + acid pickled, length can be customized; plates: solution, acid pickled, trimmed; welded pipes: solution acid pickled + RT% flaw detection, forgings: annealed + turned; bars in forged state, surface polished or turned; strips delivered in cold-rolled, solution soft state, and de-oxidized; wires delivered in solution acid pickled coil or straight bar form, solution straight bar finely polished.

Previous Page

Next Page

Previous Page

Hastelloy C-2000

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!