Product classification

Hastelloy B2

Hastelloy B2 (N10665, 2.4617) is a nickel-molybdenum alloy known for its corrosion resistance and solid solution properties. Hastelloy B2 (N10665, 2.4617) has the following characteristics: (1) Controls the content of iron and chromium at low levels to prevent the formation of the β phase Ni4Mo. (2) Excellent corrosion resistance in reducing environments. (3) Outstanding resistance to corrosion from medium concentrations of sulfuric acid and many non-oxidizing acids. (4) Good resistance to stress corrosion cracking (SCC) in the presence of chloride ions. (5) Excellent ability to resist corrosion from various organic acids.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

B2 Hastelloy Alloy Steel

1. Overview of Hastelloy B2 (N10665, 2.4617) Alloy:

Hastelloy B2 (N10665, 2.4617) is a corrosion-resistant, solid-solution nickel-molybdenum alloy. Hastelloy B2 (N10665,

2.4617) has the following characteristics:

(1) Control the content of iron and chromium at low levels to prevent the formation of β phase Ni4Mo.

(2) Excellent corrosion resistance in reducing environments.

(3) Excellent resistance to corrosion from medium concentrations of sulfuric acid and many non-oxidizing acids.

(4) Good resistance to chloride ion stress corrosion cracking (SCC).

(5) Excellent resistance to various organic acid corrosion.

2. Application range of Hastelloy B2 (N10665, 2.4617):

Hastelloy B-2 has a wide range of applications in the chemical, petrochemical, energy manufacturing, and pollution control fields, especially in industries involving sulfuric acid, hydrochloric acid, phosphoric acid, and acetic acid.

For applications in special fields, please consult the material supplier.

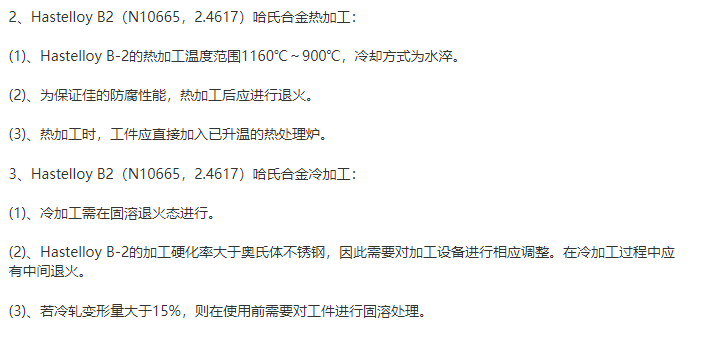

3. Processing and heat treatment of Hastelloy B2 (N10665, 2.4617):

1. Heating of Hastelloy B2 (N10665, 2.4617):

(1) It is very important to keep the workpiece clean and uncontaminated before and during heat treatment.

(2) During the heating process, it should not come into contact with sulfur, phosphorus, lead, and other low-melting-point metals, otherwise, it will damage the performance of the alloy and make Hastelloy B-2 brittle.

Care should be taken to remove stains such as marking paint, temperature indicating paint, colored crayons, chalk, lubricating oil, various liquids and oil stains, and fuel.

(3) The lower the sulfur content in the fuel, the better. The total sulfur content in natural gas and liquefied petroleum gas should be less than 0.1%, and the sulfur content in city gas should not exceed 0.25g/m3, while the sulfur content in fuel oil should be less than 0.5%.

(4) The furnace gas must be clean and slightly reducing, and fluctuations between oxidizing and reducing conditions should be avoided. The heating flame should not be directed at the workpiece.

(5) Heating should be done as quickly as possible to the required temperature.

件。

(5)、应尽量快地加热至要求的温度。

Previous Page

Next Page

Previous Page

Hastelloy C-4

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!