Product classification

4J32 precision alloy

The 4J32 alloy, also known as Super-Invar, has a lower coefficient of thermal expansion than the 4J36 alloy in the temperature range of -60 to 80°C, but its low-temperature structural stability is inferior to that of the 4J36 alloy. This alloy is mainly used for manufacturing highly precise instrument parts that require dimensional stability within a range of environmental temperature changes.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

4J32

Material grade: 4J32 precision alloy

Russian grade: 32HКД/32HК-BИ

American grade: Super-Invar/Super-Nilvar

1.Overview of 4J32 precision alloy:

The 4J32 alloy, also known as Super-Invar, has a lower expansion coefficient than the 4J36 alloy in the temperature range of -60 to 80°C, but its low-temperature microstructure stability is worse than that of the 4J36 alloy. This alloy is mainly used to manufacture precision instrument parts that require high dimensional accuracy within the range of environmental temperature changes.

1. 4J32 material grade: 4J32.

2. Similar grades to 4J32: see Table 1-1.

Table 1-1[1~4]

| Russia | USA | Japan | France |

| 32HКД 32HК-BИ |

Super-Invar Super-Nilvar |

- SI |

Invar Superieur |

3. Technical standards for 4J32 material:

4. Chemical composition of 4J32: see Table 1-2.

Table 1-2 %

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | Cu≤ |

| 0.05 | 0.02 | 0.20-0.60 | 0.020 | 0.020 | - | 31.5-33.0 | - | 0.40-0.80 |

| Others | Al≤ | Ti≤ | Fe≤ | Co≤ | V≤ | W≤ | Nb≤ | N≤ |

| - | - | Residual | 3.20-4.20 | - | - | - | - |

Under the condition that the average linear expansion coefficient meets the standard requirements, the nickel content is allowed to deviate from the range specified in Table 1-2.

5. Heat treatment system for 4J32: The performance test samples for the standard specified expansion coefficient and low-temperature microstructure stability are processed and heat-treated as follows: heat the semi-finished sample to 840°C±10°C, hold for 1 hour, water quench, then process the sample into a finished sample, and hold at 315°C±10°C for 1 hour, cooling in the furnace or air cooling.

6. Varieties, specifications, and supply status of 4J32: Varieties include bars, tubes, plates, wires, and strips.

7. Melting and casting process of 4J32: Melted using non-vacuum induction furnace, vacuum induction furnace, and electric arc furnace.

8. Application overview and special requirements of 4J32: This alloy is a typical low-expansion alloy, used for a long time in aviation factories, with stable performance. It is mainly used to manufacture precision components with high dimensional accuracy within the range of environmental temperature changes. During use, strict control of heat treatment and processing technology should be maintained, and its microstructure stability should be strictly tested according to the usage temperature.

2.Physical and chemical properties of 4J32:

1. Thermal properties of 4J32:

(1) Melting temperature range of 4J32: 1430~1450°C[1,2].

(2) Thermal conductivity of 4J32 λ=13.9W/(m•℃)[1,2].

(3) Linear expansion coefficient of 4J32: standard specifies α1(20~100℃)≤1.0×10-6℃-1[5]. The linear expansion coefficient value of 4J43 alloy and 4J36 alloy is highest after annealing above 850°C. A fast cooling rate can reduce the linear expansion coefficient. For α1(room temperature~100℃), quenching (fast cooling rate) can reduce it by nearly half compared to annealing treatment.

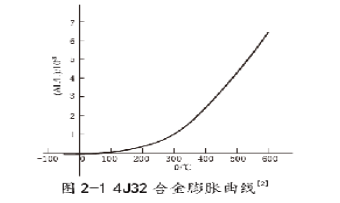

For typical composition alloys, the sample is heated to 850°C±20°C in a protective atmosphere or vacuum, held for 1 hour, and cooled to below 200°C at a rate not exceeding 300°C/h, with the average linear expansion coefficient shown in Table 2-1. The expansion curve of the alloy is shown in Figure 2-1.

Table 2-1

| Temperature range/℃ | Temperature range/℃ | ||

| 20~60 20~50 20~100 20~150 20~200 |

-0.90 0.5 0.9 1.4 2.0 |

20~250 20~300 20~400 20~500 20~600 |

3.2 4.9 7.7 9.6 10.8 |

2, 4J32 density: ρ=8.10g/cm3[1].

(1), 4J32 electrical properties

(2), 4J32 resistivity: ρ=0.77μΩ·m[1,2].

3, 4J32 temperature coefficient of resistance: see Table 2-2.

4, J32 magnetic properties:

Table 2-2[1,2]

| Temperature range/℃ | 20~50 | 20~100 | 20~200 | 20~300 | 20~400 | 20~500 |

| αR/10-3℃-1 | 1.5 | 1.4 | 1.3 | 1.0 | 0.9 | 0.8 |

(1), 4J32 Curie point: Tc=220℃[1].

(2), 4J32 alloy magnetic properties: see Table 2-3.

Table 2-3[1,2]

| H/(A/m) | B/T | H/(A/m) | B/T | H/(A/m) | B/T |

| 8 16 24 40 |

0.6×10-2 1.6×10-2 2.9×10-2 6.6×10-2 |

80 160 400 800 |

0.21 0.45 0.72 0.91 |

2000 4000 |

1.14 1.24 |

At 4000A/m, the residual magnetic induction strength Br=0.58T, coercive force Hc=75A/m[1,2].

5, 4J32 chemical properties: The alloy has certain corrosion resistance in the atmosphere, fresh water, and seawater.

Three,4J32 mechanical properties:

1, 4J32 performance specified by technical standards:

2, 4J32 mechanical properties at room temperature and various temperatures:

(1), 4J32 hardness: Alloy (annealed state) hardness HV=150[1,2].

(1), 4J32 tensile properties: The tensile properties of the alloy (annealed state) at room temperature are shown in Table 3-1.

Table 3-3[1]

| σb/MPa | σP0.2/MPa | δ/% | φ/% |

| 470 | 302 | 25 | 72 |

3, 4J32 durability and creep properties:

4, 4J32 fatigue properties:

5, 4J32 elastic properties: 4J32 elastic modulus: The elastic modulus E of the alloy (annealed state) is 141GPa.[1,2].

Four,4J32 microstructure:

1, 4J32 phase transformation temperature: γ→α phase transformation temperature is below -60℃.

2, 4J32 time-temperature-structure transformation curve:

3, 4J32 alloy microstructure: After the alloy is treated according to the heat treatment system specified in 1.5, and then cooled at -60℃ for 2h, martensitic structure should not appear. However, when the alloy composition is improper, different degrees of austenite (γ) to needle-like martensite (α) transformation will occur at room temperature or low temperature, accompanied by a volume expansion effect during the phase transformation. The expansion coefficient of the alloy increases accordingly. The main factor affecting the stability of the alloy's low-temperature structure is the chemical composition of the alloy. From the Fe-Ni-Co ternary phase diagram, it can be seen that nickel is the main element that stabilizes the γ phase. A higher nickel content is beneficial for the stability of the γ phase. Copper is also an important element for stabilizing the alloy structure. As the total deformation rate of the alloy increases, its structure tends to be more stable. Alloy composition segregation may also cause local regions of γ→α phase transformation. In addition, coarse grains can also promote the γ→α phase transformation.

Five,4J32 process performance and requirements:

1, 4J32 forming performance: This alloy is very easy to cold and hot process. During hot processing, heating in a sulfur-containing atmosphere should be avoided.

2, 4J32 welding performance: The alloy can be welded using methods such as brazing, fusion welding, and resistance welding. Since the expansion coefficient is related to the chemical composition, changes in the alloy composition should be avoided as much as possible, so argon arc welding is preferred.

3, 4J32 part heat treatment process: Heat treatment can be divided into: stress relief annealing, intermediate annealing, and stabilization treatment.

(1) Stress relief annealing: To eliminate residual stress after mechanical processing, stress relief annealing should be performed: 530~550℃, holding for 1~2h, furnace cooling.

(2) Intermediate annealing: To eliminate the work hardening phenomenon caused by cold rolling, cold drawing, and cold stamping processes, to facilitate further processing. The workpiece is heated to 830~880℃, held for 30min, and then furnace cooled or air cooled.

(3) Stabilization treatment: To obtain a lower expansion coefficient while ensuring stable performance. Generally, a three-stage treatment is used.

a) Homogenization: During heating, impurities in the alloy are fully dissolved and alloying elements tend to be uniform. The workpiece is heated to 830℃ in a protective atmosphere, held for 20min to 1h, and quenched.

b) Tempering: During the tempering process, stress generated by quenching can be partially eliminated. The workpiece is heated to 315℃, held for 1~4h, and furnace cooled.

c) Stabilization aging: To stabilize the dimensions of the alloy. The workpiece is heated to 95℃, held for 48h.

For high-precision parts after cold processing or machining, when high-temperature treatment is not suitable, the following stress relief stabilization treatment can be used: heat the workpiece to 315–370℃ for 1–4 hours.

This alloy cannot be hardened by heat treatment.

4. Surface treatment process for 4J32: Surface treatment can be done by sandblasting, polishing, or pickling. The alloy can be pickled with a 25% hydrochloric acid solution at 70℃ to remove the oxide scale.

5. Cutting and grinding performance of 4J32: The cutting characteristics of this alloy are similar to those of austenitic stainless steel. Use high-speed steel or carbide tools for low-speed cutting. Coolants can be used during cutting. This alloy has good grinding performance.

Six,Specifications and supply status of 4J32:

1. Variety classification: seamless pipes, steel plates, round steel, forgings, flanges, round rings, welded pipes, steel strips, wire materials, and matching welding materials.

2. Delivery status: Seamless pipes: solid solution + acid pickled, length can be customized; plates: solid solution, pickled, trimmed; welded pipes: solid solution acid pickled + RT% flaw detection, forgings: annealed + turned; bars in forged and rolled state, surface polished or turned; strips delivered in cold-rolled, solid solution soft state, and deoxidized; wire materials delivered in solid solution acid pickled coil or straight bar form, solid solution straight bar finely polished.

Previous Page

Next Page

Previous Page

4J33 precision alloy

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!