Product classification

4J36 precision alloy

The 4J36 alloy, also known as Invar, has a Curie point of approximately 230°C. Below this temperature, the alloy is ferromagnetic and has a very low coefficient of expansion, while above this temperature, the alloy becomes non-magnetic and the coefficient of expansion increases. This alloy is mainly used to manufacture components that maintain a nearly constant size within a range of temperature variations, and it is widely used in the radio industry, precision instruments, gauges, and other industries.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

4J36

Material grade: 4J36 precision alloy

Russian grade: 32H/32H-BИ

American grade: Invar/Nilvar/Unipsan 36

British grade: Nilo36/36Ni

German grade: Vacodil36/Nilos36

1.Overview of 4J36 precision alloy:

The 4J36 alloy, also known as Invar, has a Curie point of about 230°C. Below this temperature, the alloy is ferromagnetic and has a very low expansion coefficient; above this temperature, the alloy is non-magnetic and the expansion coefficient increases. This alloy is mainly used to manufacture components that maintain a nearly constant size within a range of temperature variations, widely used in the radio industry, precision instruments, gauges, and other industries.

1. 4J36 material grade: 4J36.

2. Similar grades to 4J36: see Table 1-1.

Table 1-1[1,2]

| Russia | USA | UK | Japan | France | Germany |

| 32H 32H-BИ - |

Invar Nilvar Unipsan 36 |

Invar Nilo36 36Ni |

Invar steel Cactus LE - |

Invar Standard Fe-Ni36 - |

Vacodil36 Nilos36 - |

3. Technical standards for 4J36 material:

4. Chemical composition of 4J36: see Table 1-2.

Table 1-2 %

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | Cu≤ |

| 0.05 | 0.30 | 0.20-0.60 | 0.020 | 0.020 | - | 35.0-37.0 | - | - |

| Others | Al≤ | Ti≤ | Fe≤ | Co≤ | V≤ | W≤ | Nb≤ | N≤ |

| - | - | Residual | - | - | - | - | - |

Under the condition that the average linear expansion coefficient meets the standard requirements, the nickel content is allowed to deviate from the range specified in Table 1-2.

5. Heat treatment system for 4J36: The samples for the performance test of the expansion coefficient as specified in the standard are processed and heat-treated as follows: heat the semi-finished sample to 840°C±10°C, hold for 1 hour, quench in water, then process the sample into a finished sample, and hold at 315°C±10°C for 1 hour, cool in the furnace or air cool.

6. Varieties, specifications, and supply status of 4J36: Varieties include bars, tubes, plates, wires, and strips.

7. Melting and casting process of 4J36: Melted using non-vacuum induction furnace, vacuum induction furnace, and electric arc furnace.

8. Application overview and special requirements of 4J36: This alloy is a typical low-expansion alloy. It has been used for a long time in aviation factories, with stable performance; during use, strict control of heat treatment and processing technology should be maintained to ensure the stability of the material.

2.Physical and chemical properties of 4J36:

1. Thermal properties of 4J36:

(1) Melting temperature range of 4J36: 1430~1450°C.[1,2].

(2) Thermal conductivity of 4J36: λ=11W/(m•°C).[1,2].

(3) Specific heat capacity of 4J36: c(20~100°C)=515J/(kg•°C).

(4) Linear expansion coefficient of 4J36: The standard specifies α1(20~100°C)≤1.5×10-6°C-1.

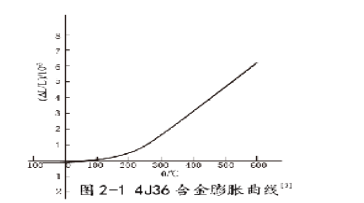

The alloy sample is heated to 880°C±20°C in a protective atmosphere or vacuum, held for 1 hour, and cooled at a rate not exceeding 300°C/h. The average linear expansion coefficient is shown in Table 2-1. The expansion curve of the alloy is shown in Figure 2-1.

Table 2-1[1]

| Temperature range/°C | Temperature range/°C | ||

| 20~60 | 1.8 | 20~250 | 3.6 |

| 20~40 | 1.8 | 20~300 | 5.2 |

| 20~20 | 1.6 | 20~350 | 6.5 |

| 20~0 | 1.6 | 20~400 | 7.8 |

| 20~50 | 1.1 | 20~450 | 8.9 |

| 20~100 | 1.4 | 20~500 | 9.7 |

| 20~150 | 1.9 | 20~550 | 10.4 |

| 20~200 | 2.5 | 20~600 | 11.0 |

2, 4J36 density: ρ=8.10g/cm3[1].

3, 4J36 electrical properties:

(1), 4J36 resistivity: ρ=0.78μΩ·m[1,2].

(2), 4J36 temperature coefficient of resistance: see Table 2-2.

Table 2-2[1,2]

| Temperature range/°C | 20~50 | 20~100 | 20~200 | 20~300 | 20~400 | 20~500 |

| αR/103°C-1 | 1.8 | 1.7 | 1.4 | 1.2 | 1.0 | 0.9 |

4, 4J36 magnetic properties:

(1), 4J36 Curie point: Tc=230℃[1,2].

(2), Magnetic properties of J36 alloy (strip): see Table 2-3.

Table 2-3[1,2]

| H/(A/m) | B/T | H/(A/m) | B/T |

| 8 | 1.8×10-2 | 160 | 0.74 |

| 16 | 4.2×10-2 | 400 | 0.97 |

| 24 | 8×10-2 | 800 | 1.12 |

| 40 | 0.2 | 2000 | 1.27 |

| 80 | 0.5 | 4000 | 1.32 |

At 4000A/m, residual magnetic induction Br=0.6T, coercive force Hc=48A/m[1,2].

(3), The relationship between the magnetic permeability of 4J36 alloy and temperature (magnetic field strength 400A/m): see Table 2-4.

Table 2-4[1,2]

| θ/℃ | -17.8 | 10.0 | 37.8 | 66 | 93 | 116 |

| μ/(mH/m) | 2.25 | 2.14 | 2.04 | 1.93 | 1.81 | 1.70 |

5, 4J36 chemical properties: The alloy has certain corrosion resistance in the atmosphere, fresh water, and seawater.

Three,4J36 mechanical properties:

1, Performance specified by 4J36 technical standards:

2, Mechanical properties of 4J36 at room temperature and various temperatures:

(1), 4J36 hardness: The hardness of the alloy in the annealed state is HV=140.[1,2].

(2), 4J36 tensile properties: The tensile properties of the alloy (annealed state) at room temperature are shown in Table 3-1. The tensile properties under different cold strain are shown in Table 3-2.

Table 3-1[1]

| σb/MPa | σP0.2/MPa | δ/% |

| 450 | 274 | 35 |

Table 3-2

| ε/% | σb/MPa | σP0.2/MPa | δ/% |

| 15 25 30 |

641 689 731 |

448 617 655 |

14 9 8 |

3, 4J36 durability and creep properties:

4, 4J36 fatigue properties:

5, 4J36 elastic properties:

6, 4J36 elastic modulus: The elastic modulus of the alloy (annealed state) is E=144GPa.

Four,4J36 microstructure:

1, 4J36 phase transformation temperature:

2, 4J36 time-temperature-structure transformation curve:

3, 4J36 alloy microstructure: The alloy has a single-phase austenitic structure.

4, 4J36 grain size: For a strip with a cold strain rate ε=60%~70% and thickness d=1mm, after annealing for 1h at the temperature shown in Table 4-1 and air cooling, the grain size rating is conducted according to YB 027-1992 standard, and the results are shown in Table 4-1.

Table 4-1[1,2]

| Annealing temperature/℃ | 700 | 750 | 800 | 900 | 1000 | 1050 | 1100 | 1200 |

| Grain size level | Start of recrystallization | >10 | >10 | 9.0 | 6.5 | 4.0 | 3.0 | 2.0 |

Five,4J36 process performance and requirements:

1, 4J36 forming performance: The alloy is very easy to process both cold and hot. During hot processing, heating in a sulfur-containing atmosphere should be avoided.

2, 4J36 welding performance: The alloy can be welded using methods such as oxy-acetylene welding, arc welding, spot welding, and hydrogen atom welding. Since the expansion coefficient is related to the chemical composition of the alloy, changes in the alloy composition due to welding should be avoided as much as possible. Therefore, argon arc welding is preferred, and the filler metal used for welding should preferably contain 0.5% to 1.5% titanium to reduce welding porosity and cracks.

3, 4J36 part heat treatment process: The heat treatment of this alloy can be divided into: stress relief annealing, intermediate annealing, and stabilization treatment.

(1) Stress relief annealing: To eliminate residual stress in parts after machining, stress relief annealing should be performed: 530~550℃, holding for 1~2h, furnace cooling.

(2) Intermediate annealing: To eliminate the work hardening caused by cold rolling, cold drawing, and cold stamping processes, facilitating further processing. The workpiece is heated to 830~880℃, held for 30min, and then furnace cooled or air cooled.

(3) Stabilization treatment: To obtain a treatment with a lower expansion coefficient while ensuring stable performance. Generally, a three-stage treatment is adopted.

a) Homogenization: During heating, impurities in the alloy are fully dissolved and alloying elements tend to be uniform. The workpiece is heated to 830℃ in a protective atmosphere, held for 20 minutes to 1 hour, and then quenched.

b) Tempering: The tempering process can partially eliminate the stresses generated by quenching. The workpiece is heated to 315℃, held for 1 to 4 hours, and then cooled in the furnace.

c) Stabilization aging: To stabilize the dimensions of the alloy. The workpiece is heated to 95℃ and held for 48 hours. For high-precision parts after cold working or machining, high-temperature treatment is not advisable; instead, the following stress-relief stabilization treatment can be used: heat the workpiece to 315 to 370℃ for 1 to 4 hours.

This alloy cannot be hardened by heat treatment.

4. 4J36 surface treatment process: Surface treatment can be done by sandblasting, polishing, or pickling. The alloy can be pickled with a 25% hydrochloric acid solution at 70℃ to remove oxide scale.

Previous Page

Next Page

Previous Page

4J32 precision alloy

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!