Product classification

Gh3170

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

GH3170 is a Ni-Cr-Co based solid solution strengthened deformation high-temperature alloy, widely used in aerospace, petrochemical and other fields due to its excellent performance and processing weldability at high temperatures. The composition of this alloy is characterized by a high proportion of tungsten (W), cobalt (Co), and chromium (Cr), with a trace amount of lanthanum (La) added to strengthen the grain boundaries. GH3170 has high strength and good creep resistance at 1000℃, and still maintains good strength at 1100℃-1200℃.

Introduction to GH3170

GH3170 has been used to manufacture parts for the afterburner adjustment of aircraft engines, with performance levels close to the American solid solution strengthened cobalt-based alloys HA188 and MAR-M918. The alloy precipitates the μ phase after long-term aging at 900℃ and 1000℃, which reduces the room temperature plasticity of the alloy, but it can still meet the usage requirements.

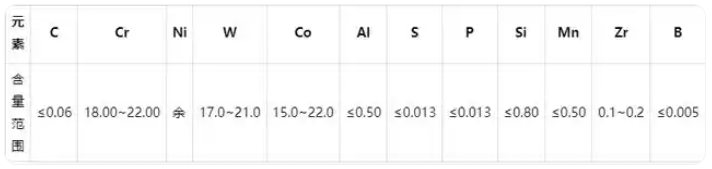

Chemical Composition

The chemical composition of GH3170 is shown in the table below:

Physical Properties

The physical properties of GH3170 include:

· Melting temperature range: 1395℃~1425℃

· Density: 9.34 g/cm³

· Magnetic properties: The alloy is non-magnetic.

Mechanical Properties

The mechanical properties of GH3170 are as follows:

· Room temperature tensile properties of cold-rolled thin plates after heat treatment at 1230℃±10℃/AC: σb≥735 MPa, δ5≥40%.

· At 1000℃, σb≥135 MPa, δ5≥40%, and durability performance z/h≥100.

Processing and Welding Performance

GH3170 can be welded using spot welding, seam welding, and argon arc welding, with a joint strength coefficient greater than 85%.

Application Fields

GH3170 is widely used in:

1. Combustion chambers and other high-temperature components of aircraft engines.

2. Nozzle materials for rocket engines.

3. High-temperature applications in the petrochemical field.

Characteristics and Advantages

GH3170 is known for its excellent high-temperature performance, oxidation resistance, and good cold forming and welding process performance. At high temperatures of 1000℃, GH3170 can maintain high strength and good resistance to deformation, and even at extreme temperatures of 1100℃ to 1200℃, this alloy still exhibits good strength.

Previous Page

Gh3028

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!