Product classification

Gh3181

GH3181 is a Ni-Cr based solid solution strengthened deformation high-temperature alloy, with a usage temperature range of 900°C to 1200°C. This alloy has various excellent properties and is widely used in many fields.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

Overview of GH3181 High-Temperature Alloy

GH3181 is a Ni-Cr based solid solution strengthened deformation high-temperature alloy, with a temperature range of 900℃ - 1200℃. This alloy has various excellent properties and is widely used in many fields.

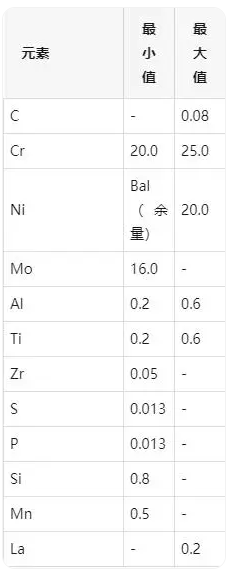

1. Chemical Composition

The chemical composition of GH3181 high-temperature alloy (mass fraction, %) is as follows:

2. Physical Properties

DensityAccording to different sources, the density value varies, with some data showing 7.8g/cm³ and others showing 9.29g/cm³, which may be due to the specific composition or state of the alloy (such as after heat treatment).

Thermal Conductivity12.5W/m·K (this value is for reference only, the specific value may vary due to the alloy's state and environmental conditions).

3. Mechanical Properties

High-Temperature StrengthIn the temperature range of 600 - 800℃, the GH3181 alloy can maintain high tensile strength and yield strength.

Creep ResistanceUnder long-term high temperatures, the alloy exhibits good creep resistance.

Resistance to Thermal FatigueIt can withstand repeated thermal cycles without fracturing.

4. Corrosion Resistance

Oxidation ResistanceIn a high-temperature environment of 800℃, the GH3181 alloy shows good oxidation resistance, maintaining a smooth surface for a long time.

Corrosion ResistanceIn environments with sulfur-containing gases and salt mist, the alloy exhibits excellent corrosion resistance, especially in high-temperature and high-pressure environments, where its corrosion resistance is superior to similar materials. In chloride solutions, the alloy also shows strong stress corrosion resistance.

5. Machinability

The GH3181 alloy exhibits high plasticity during hot and cold processing, making it suitable for manufacturing complex-shaped components. Additionally, this alloy has good welding performance and can be welded using various methods such as TIG, MIG, and manual arc welding, ensuring the quality and strength of the weld joints, further enhancing the reliability and service life of the components.

6. Application Fields

Aerospace FieldIt is a key material for manufacturing high-temperature components of aircraft engines and rocket engines (such as combustion chambers, turbine discs, nozzles, etc.), providing strong assurance for the safe flight of aircraft.

Nuclear Energy IndustryIt can be used to manufacture heat exchangers that withstand high-temperature and high-pressure steam erosion and have corrosion resistance, providing important support for the safe operation of nuclear reactors.

Petrochemical FieldDue to its good oxidation and corrosion resistance, it can be used to manufacture nozzles and other equipment that withstand high-temperature and high-pressure liquid erosion and require corrosion resistance.

Other AspectsThis alloy is resistant to liquid sodium corrosion at high temperatures and can be used as structural material for high-temperature sodium heat pipes, as well as suitable for making high-temperature components such as gas turbine flame tubes.

Previous Page

Gh3170

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!