Product classification

Inconel 718

Inconel 718 alloy is a nickel-based superalloy that is precipitation strengthened by body-centered cubic phase (y") and face-centered cubic phase (γ). It exhibits excellent comprehensive performance in the temperature range of -253 to 700°C, with the highest yield strength among deformed high-temperature alloys below 650°C, as well as good fatigue resistance, radiation resistance, oxidation resistance, and corrosion resistance. It also has good machinability, weldability, and long-term microstructural stability, allowing for the manufacture of complex-shaped components. It has found extensive applications in aerospace, nuclear energy, and the petroleum industry within the aforementioned temperature range.

Classification:

Key words:

Superalloy | Inkenel | Hastelloy | Inkloy | Precision Alloy Series

Product Parameters

Inconel 718

Material grade: Inconel 718 nickel-based alloy

US grade: N07718

German grade: W.Nr.2.4668/NiCr19Fe19Nb5

French grade: Nc19FeNb

1. Overview of Inconel 718 (N07718) nickel-based alloy:

Inconel 718 alloy is a nickel-based high-temperature alloy strengthened by precipitation of body-centered tetragonal δ and face-centered cubic γ phases. It has good comprehensive performance in the temperature range of -253 to 700°C, with yield strength below 650°C ranking first among deformed high-temperature alloys, and exhibits excellent fatigue resistance, radiation resistance, oxidation resistance, corrosion resistance, as well as good machinability, weldability, and long-term microstructure stability. It can be used to manufacture various complex-shaped components and has found extensive applications in aerospace, nuclear energy, and petroleum industries within the aforementioned temperature range.

Another characteristic of this alloy is that its microstructure is particularly sensitive to thermal processing. By mastering the precipitation and dissolution laws of phases in the alloy and the interrelationship between microstructure and process performance, reasonable and feasible process specifications can be formulated according to different usage requirements, thus obtaining various parts that meet different strength levels and usage requirements. The supplied varieties include forgings, forged bars, rolled bars, cold-rolled bars, discs, rings, plates, strips, and tubes, which can be made into discs, ring blades, shafts, fasteners, elastic components, plate structural parts, casings, and other components for long-term use in aviation.

1. Inconel 718 material grade: Inconel 718.

2. Inconel 718 similar grades: Inconel 718 (USA), NC19FeNb (France).

3. Technical standards for Inconel 718 material.

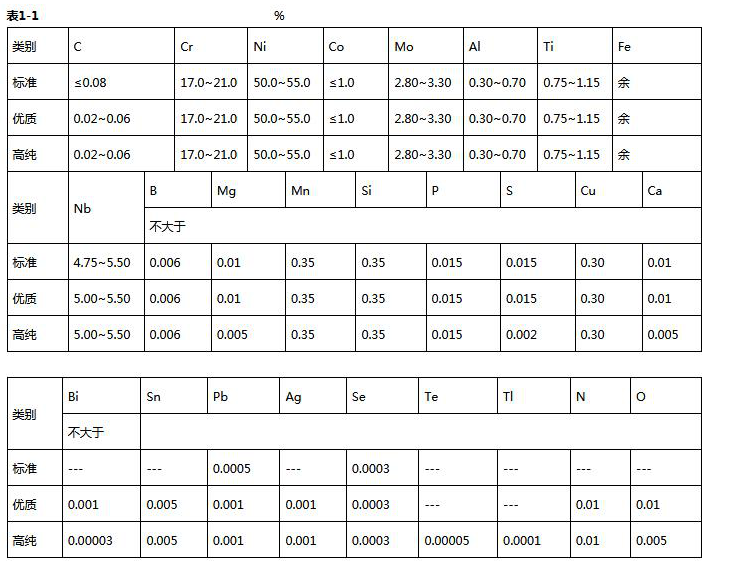

4. Inconel 718 chemical composition: The chemical composition of this alloy is divided into three categories: standard composition, high-quality composition, and high-purity composition, as shown in Table 1-1. The high-quality composition reduces carbon and increases niobium based on the standard composition, thereby reducing the amount of niobium carbide, decreasing fatigue sources, and increasing the number of strengthening phases, improving fatigue resistance and material strength. At the same time, it reduces harmful impurities and gas content. The high-purity composition reduces the sulfur and harmful impurities content based on the high-quality standard, improving material purity and comprehensive performance.

For Inconel 718 alloy used in nuclear energy applications, the boron content must be controlled (other elemental compositions remain unchanged), and the specific content is determined through negotiation between the supply and demand parties. When ω(B) is 0.002%, to distinguish it from the Inconel 718 alloy used in the aerospace industry, the alloy grade is Inconel 718A.

5. Inconel 718 heat treatment system: The alloy has different heat treatment systems to control grain size, phase morphology, distribution, and quantity, thereby obtaining different levels of mechanical properties. The alloy heat treatment system is divided into three categories:

(1). (1010~1065)°C + 109°C, 1h, oil cooling, air cooling, or water cooling + 720°C + 5°C, 8h. Cool to 620°C + 5°C at 50°C/h, 8h, air cooling. The material treated by this system has coarsened grains, with no δ phase at grain boundaries and within grains, showing notch sensitivity, but it is beneficial for improving impact performance and resisting low-temperature hydrogen embrittlement.

(2). (950~980)°C + 10°C, 1h, oil cooling, air cooling, or water cooling + 720°C + 5°C, 8h. Cool to 620°C + 5°C at 50°C/h, 8h, air cooling. The material treated by this system contains δ phase, which helps eliminate notch sensitivity, and is the most commonly used heat treatment system, also known as the standard heat treatment system.

(3) 720°C + 5°C, 8h, cool to 620°C + 5°C at 50°C/h, 8h, air cooling. After treatment by this system, the material contains less δ phase, which can improve the strength and impact performance of the material. This system is also known as the direct aging heat treatment system.

6. Inconel 718 varieties, specifications, and supply status: Forgings (discs, integral forgings), cakes, rings, bars (forged bars, rolled bars, cold-drawn bars), plates, wires, and pipes of different shapes and sizes can be supplied. The delivery status is agreed upon by the supply and demand parties. Wires are delivered in coil form as per the agreed delivery status.

7. Inconel 718 smelting and casting process: The smelting process of the alloy is divided into three categories: vacuum induction melting with electroslag remelting; vacuum induction melting with vacuum arc remelting; vacuum induction melting with electroslag remelting plus vacuum arc remelting. The required smelting process can be selected according to the usage requirements of the parts to meet application requirements.

8. Overview of Inconel 718 applications and special requirements: Used to manufacture various stationary and rotating parts in aviation and aerospace engines, such as discs, rings, casings, shafts, blades, fasteners, elastic components, gas ducts, sealing components, and welded structural parts; used to manufacture various elastic components and frames for nuclear energy applications; used to manufacture parts and other components for the petroleum and chemical industries. In recent years, based on the continuous deepening of research on this alloy and the expanding applications of this alloy, many new processes have been developed to improve quality and reduce costs: vacuum arc remelting uses helium gas cooling technology to effectively reduce niobium segregation; injection molding technology is used to produce ring parts, reducing production costs and shortening production cycles; superplastic forming technology is used to expand the production range of products.

2. Physical and chemical properties of Inconel 718:

1. Thermal properties of Inconel 718:

(1) Melting temperature range of Inconel 718: 1260 ~ 1320°C.

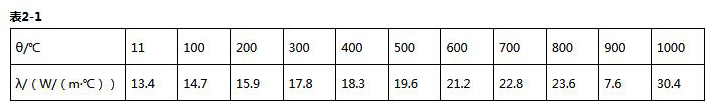

(2) Thermal conductivity of Inconel 718: see Table 2-1.

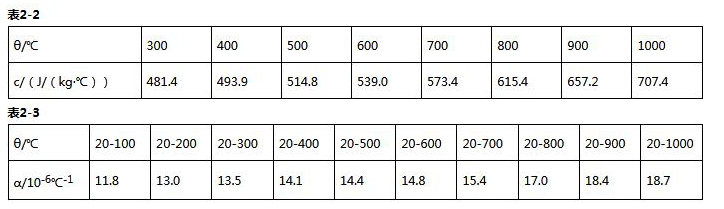

(3) Specific heat capacity of Inconel 718: see Table 2-2.

(4) Linear expansion coefficient of Inconel 718: see Table 2-3.

2. Density of Inconel 718: p=8.24g/cm3.

3. Electrical properties of Inconel 718:

4. Magnetic properties of Inconel 718: non-magnetic.

3. Inconel718电性能:

4. Inconel718磁性能:台金无磁性。

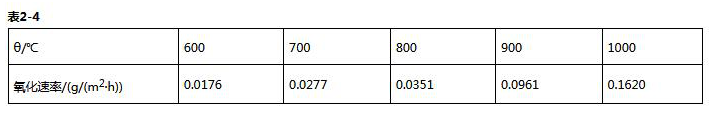

5. Chemical properties of Inconel718: Oxidation resistance of Inconel718: The oxidation rate after 100 hours of testing in air is shown in Table 2-4.

3. Main characteristics and application fields of Inconel718:

1. Main characteristics:

(1) Easy machinability

(2) High tensile strength, fatigue strength, creep strength, and fracture strength at 700°C

(3) High oxidation resistance at 1000°C

(4) Stable chemical properties at low temperatures

(5) Good welding performance.

2. Application fields of Inconel718: Due to its high-temperature strength and excellent corrosion resistance at 700°C, as well as its machinability, it can be widely used in various high-demand situations.

(1) Turbines

(2) Liquid fuel rockets

(3) Cryogenic engineering

(4) Acidic environments

(5) Nuclear engineering

4. Varieties, specifications, and supply status of Inconel718:

1. Classification: Inconel718 seamless pipes, Inconel718 steel plates, Inconel718 round bars, Inconel718 forgings, Inconel718 flanges, Inconel718 rings, Inconel718 welded pipes, Inconel718 steel strips, Inconel718 wires and matching welding materials.

2. Supply status: Seamless pipes: solution + acid pickling, length can be customized; plates: solution, acid pickling and edge cutting; welded pipes: solution acid pickling + RT% flaw detection, forgings: annealed + turned; bars are polished or turned in forged state; strips are delivered after cold rolling, solution soft state, and descaling; wires are delivered in solution acid pickled coil or straight bar form. Solution straight bars are delivered in fine polished state.

Previous Page

Next Page

Previous Page

Inconel X-750

Next Page

Related Products

Product Consulting

Leave your contact information to get a free product quote!